jar546

CBO

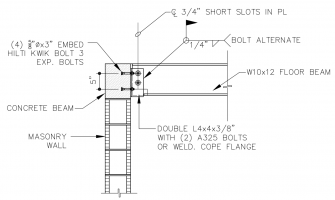

The contractor missed a weld plate (embed plate) and in the RFI the engineer specified expansion bolts. This is the result of the expansion bolts. Looks like they probably hit the rebar and the hole went in at an angle. Now we have one problem and the fix created another. What has engineers in your area done for situations like this?

The two bolts on the other side are in straight.

The two bolts on the other side are in straight.