ICE

Oh Well

R317.3.1 Fasteners for preservative-treated wood. Fas- teners, including nuts and washers, for preservative- treated wood shall be of hot-dipped, zinc-coated galva- nized steel, stainless steel, silicon bronze or copper. Coat- ing types and weights for connectors in contact with preservative-treated wood shall be in accordance with the connector manufacturer’s recommendations. In the absence of manufacturer’s recommendations, a minimum of ASTM A653 type G185 zinc-coated galvanized steel, or equivalent, shall be used.

Exceptions:

1. 1/2-inch-diameter (12.7 mm) or greater steel bolts.

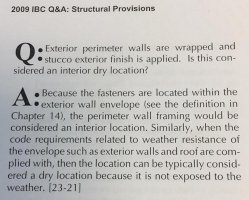

Do you consider the mud sill of an exterior wall to be an interior, dry environment?

Exceptions:

1. 1/2-inch-diameter (12.7 mm) or greater steel bolts.

- Fasteners other than nails and timber rivets shall be permitted to be of mechanically deposited zinc-coated steel with coating weights in accor- dance with ASTM B695, Class 55 minimum.

- Plain carbon steel fasteners in SBX/DOT and zinc borate preservative-treated wood in an interior, dry environment shall be permitted.

Do you consider the mud sill of an exterior wall to be an interior, dry environment?

Last edited: