Why was it added as a footnote to the post sizing table, and not as an exemption to 507.5.1? Great, you have a post cap that can fit a 5.5-in wide beam and connect to a 4x4 post, but it does not meet 507.5.1 which requires full bearing width."we may never fully know..." UH... yeah, it's no secret. I know and I'm trying to help you know, so that "we can fully know". I know all the people that created it and I worked with them on 2015, 2021 and already starting on 2024 If you're looking for hidden agendas, they aren't there. It's collaborative work by many different parties.

I'll try one more time to explain why the 2018 change was important.

This has nothing to do with approving a post cap. It has everything to do with approving a post height from a table who's engineering is only based on a 2 ply beam max span, and the maximum trib area that can be created, and then also approving a post cap to bear a three ply beam which can be sized by the code. It was a mistake in the assumptions made that a 4x4 would always only carry a 2-ply beam. A code user that does not realize the derivation of the maximum 4x4 height would not have been prompted to question it supporting a 3-ply for any reason other than the beam bearing. Such as:

"OH! you have a tested post cap for that 3-ply beam on a 4x4. No problem then." The problem is there is a problem, but it's not the beam or post cap. It's the load on the post from a three ply beam (and resulting trib area) that may now exceed what the post sizing was based on.

This is not anywhere near engineering necessity. It's a tested post cap.

I don't really know how else I can explain this. Its the inherent difficult of created pre-engineered tables. Assumptions have to be made, but they also have to be known.

Truthfully, deck codes are a brand new work in progress in codes that have been in works for over a hundred years. The 2015 and 2018 provisions should be thrown away as trial and error that has brought us to the 2021. When 2024 is done, I will say the same of throwing away the 2021. It is going to take a few cycles to plateau at a complete prescriptive set of deck structural codes.

Again, happy to answer questions, but I'm starting to feel like maybe you've already made up your minds. If you had seen my visual presentation in my recent webinar, I think you would fully see whats going on.

-

Welcome to the new and improved Building Code Forum. We appreciate you being here and hope that you are getting the information that you need concerning all codes of the building trades. This is a free forum to the public due to the generosity of the Sawhorses, Corporate Supporters and Supporters who have upgraded their accounts. If you would like to have improved access to the forum please upgrade to Sawhorse by first logging in then clicking here: Upgrades

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

deck

- Thread starter linnrg

- Start date

Why was it added as a footnote to the post sizing table, and not as an exemption to 507.5.1? Great, you have a post cap that can fit a 5.5-in wide beam and connect to a 4x4 post, but it does not meet 507.5.1 which requires full bearing width.

You. Are. Killing. Me. Ha, ha!

It's a tested post cap. Every single mechanical connector is an alternative. You don't write exceptions for alternatives, you review the evidence submitted and you approve them. R507.5.1 is not about beams bearing in alternative bearing devices. Again, the 1 1/2" bearing lengths DO NOT APPLY TO CONNECTORS. Alternatives (connectors) can appear like magic when compared to prescriptive design. Prescriptive design is like making a meal from the better homes and garden cookbook all our grandmas have. VERY LIMITED. A tested post cap is like having Wolfgang Puck come to your home and make dinner. His methods will be quite different than the cook book.

"most" post caps are only designed for uplift and lateral displacement, but "some" post caps include bearing enhancing, like the ones we are talking about. You approve the alternative bearing as an alternative to 507.5.1. This is no different than...

"most" trusses get a truss clip for uplift, but "some" trusses with larger bearing loads, also get a truss bearing enhancement (TBE). Same thing. Its an alternative to providing a thicker wall for more bearing area.

It has to be in the post sizing table because (dear Lord, I'm saying it again), the post height limits are based on an assumed maximum tributary area of a 2-ply beam! 8 ft. is too tall for maximum loads with a IRC designed 3-ply beam.

I hope I don't confuse this, but think of approving a really tall and long 3.5" wide glued-laminated beam through a beam span table provided by the manufacturer. You will suddenly be able to get a really long beam (longer than a prescriptive 2 2x12) and you will put way more tributary area on a 4x4 post than the IRC table was ever designed for. The IRC, however, is clear the post supporting that glue-lam can no longer be sized with the IRC table we are discussing.

Notice we handled that in R507.4 where it says "beams sized in accordance with Table R507.5..." So the pointer to the post sizing table restricts it's use to only beams sized by the IRC beam table. Glue-lams aren't there. UH-OH... 3-ply beams are... but the larger areas were not part of the engineering behind the limits for a 4x4.

Glenn ... I appreciate what you doing to improve the codes, and I’m not trying to be critical. Just trying to understand. I do get your point about 4x4 vs 6x6 posts when height is factored in. That was good to see.

Ty ... Why don’t you like the z bracket? Except that its designed for beams passing along side the post, not bearing on top.

Ty ... Why don’t you like the z bracket? Except that its designed for beams passing along side the post, not bearing on top.

Because 9 out of 10 times that I see these submitted, the proponent wants to consider the girder as a 2-ply member when in reality, there is 3.5-in between the plies. The result is the interior member carries the full load until it deflects sufficiently to load the outer member (which at least initially, is in uplift).Ty ... Why don’t you like the z bracket? Except that its designed for beams passing along side the post, not bearing on top.

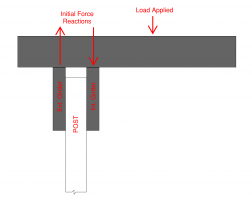

Here is my pictorial representation.

Because 9 out of 10 times that I see these submitted, the proponent wants to consider the girder as a 2-ply member when in reality, there is 3.5-in between the plies. The result is the interior member carries the full load until it deflects sufficiently to load the outer member (which at least initially, is in uplift).[/ATTACH]

BAM! Excellent. You are spot on. The other issue is top chord bending. With less thickness there is less resistance to the beam bending out of plane and thus deflecting more. You are going to appreciate what we did for the 2021 on this subject. It's subtle, but it speaks to this issue.

Look at RB188-19 at this link. It's on page 460 of the PDF. We added the word "together" Just to help out a bit with the point.

http://media.iccsafe.org/code-development/group-b/IRC-B-compressed.pdf

Glenn ... I appreciate what you doing to improve the codes, and I’m not trying to be critical. Just trying to understand. I do get your point about 4x4 vs 6x6 posts when height is factored in. That was good to see.

Thanks. I like critical thinking and discussions about this stuff. I want to the code to be clear. I actually realized some issues from this conversation that I'll address in 2024. Such as now that the post sizing table is based on tributary load, R507.4 no longer has to limit to table to prescriptive beams. Glu-lams, the new treated LVLs, and other longer-spanning beams could have posts sized under Table R507.4. The minimum bearing area, however, would come from the beam span design, and not the IRC 1 1/2".

steveray

SAWHORSE

but it does not meet 507.5.1 which requires full bearing width.

It does bear fully...On the METAL post cap.....More than the prescriptive 1.5".....

Paul Sweet

Sawhorse

Compression perpendicular to the grain usually limits the load of a beam on a post before you reach the limits of bending in the beam or compression of the post (unless it's a long enough post for Euler buckling to limit compression). You have to check all 3. Any prescriptive limit will be extremely conservative.

steveray

SAWHORSE

Euler? Euler? Euler.......?

ADAguy

Registered User

!. after "all" this I have not heard mention of research reports or an S.E.'s opinion.

2. Simpson can't be the only" company making tested post caps?

3. This all seems to be directed to DIY'rs, no? They would just toe nail it!

4. Lastly what are the dynamic load limits (safety factors) imposed by deck users shoulder to shoulder with beers and BBQ jumping up and down and moving side to side?

2. Simpson can't be the only" company making tested post caps?

3. This all seems to be directed to DIY'rs, no? They would just toe nail it!

4. Lastly what are the dynamic load limits (safety factors) imposed by deck users shoulder to shoulder with beers and BBQ jumping up and down and moving side to side?

Years ago both home depot and lowes carried a wide range of simpson products, then i noticed that one of them ... lowes i think ... switched to a different brand. Cost saving move I’m sure. The new brand didn’t seem to have the same quality, and the metal seemed to be a bit thinner.!.

2. Simpson can't be the only" company making tested post caps?

On the construction side people bad mouthed simpson, saying they were driving their business by convincing BO’s to spec their product. Maybe. But it’s a good product, and if you install it properly it enhances the build. And for DIY folks it probably prevents a lot of failures.