-

Welcome to the new and improved Building Code Forum. We appreciate you being here and hope that you are getting the information that you need concerning all codes of the building trades. This is a free forum to the public due to the generosity of the Sawhorses, Corporate Supporters and Supporters who have upgraded their accounts. If you would like to have improved access to the forum please upgrade to Sawhorse by first logging in then clicking here: Upgrades

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Birds Mouth

- Thread starter alaskajoe

- Start date

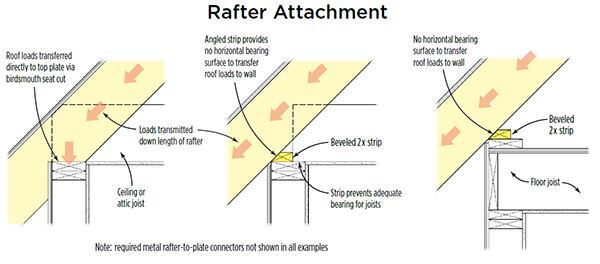

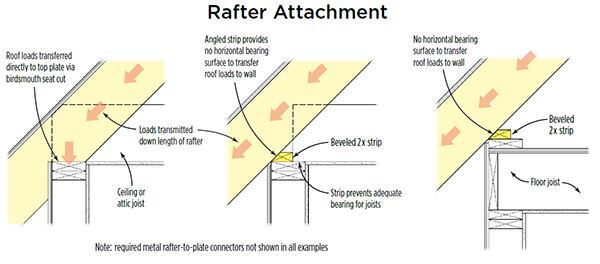

How else are you going to get sufficient bearing for the rafter on the top plate? If you don’t cut a birds mouth, the only point of contact will be the intersection of the outboard edge of the plate and where it touches the rafter.

FYI, the code requirement is established as follows:

R802.6 Bearing

The ends of each rafter or ceiling joist shall have not less than 1-1/2 inches (38 mm) of bearing on wood or metal and not less than 3 inches (76 mm) on masonry or concrete. The bearing on masonry or concrete shall be direct, or a sill plate of 2-inch (51 mm) minimum nominal thickness shall be provided under the rafter or ceiling joist. The sill plate shall provide a minimum nominal bearing area of 48 square inches (30 865 mm2).

R802.7.1.1 Cantilevered Portions of Rafters

Notches on cantilevered portions of rafters are permitted provided the dimension of the remaining portion of the rafter is not less than 31/2 inches (89 mm) and the length of the cantilever does not exceed 24 inches (610 mm) in accordance with Figure R802.7.1.1.

For SI: 1 inch = 25.4 mm.

FIGURE R802.7.1.1 RAFTER NOTCH

The ends of each rafter or ceiling joist shall have not less than 1-1/2 inches (38 mm) of bearing on wood or metal and not less than 3 inches (76 mm) on masonry or concrete. The bearing on masonry or concrete shall be direct, or a sill plate of 2-inch (51 mm) minimum nominal thickness shall be provided under the rafter or ceiling joist. The sill plate shall provide a minimum nominal bearing area of 48 square inches (30 865 mm2).

R802.7.1.1 Cantilevered Portions of Rafters

Notches on cantilevered portions of rafters are permitted provided the dimension of the remaining portion of the rafter is not less than 31/2 inches (89 mm) and the length of the cantilever does not exceed 24 inches (610 mm) in accordance with Figure R802.7.1.1.

For SI: 1 inch = 25.4 mm.

FIGURE R802.7.1.1 RAFTER NOTCH

I like the per se comment. I just couldn't find anything saying it has to be there but don't know why you wouldn't put one on the rafter. For download bearing it is the best way to transfer the load. A bevel strip albeit something doesn't transfer the load the same way. Just dealing with someone who likes arguing with the inspector as per your quote Ty

I can't foresee why anyone who was framing with rafters would not use a birds mouth, but I also acknowledge that the code does not outright require it. Just a minimum of 1-1/2-in bearing.I like the per se comment. I just couldn't find anything saying it has to be there but don't know why you wouldn't put one on the rafter. For download bearing it is the best way to transfer the load. A bevel strip albeit something doesn't transfer the load the same way. Just dealing with someone who likes arguing with the inspector as per your quote Ty

I am not a fan of shims, beveled plates and blocks, etc., as each of these methods relies on mechanical attachment to keep the rafter from thrusting off the plate. A birdsmouth notch is a much cleaner transfer of the forces.

I dont like strips either because they always seem to split when trying to fasten.. In the stage its at here I will have a bevel and also have a Simpson beam/rafter tie on each rafter. I don't know why one wouldn't cut birds mouth into rafter also unless they don't know how.

Here is a decent article on the subject.

https://www.jlconline.com/how-to/framing/are-birdmouths-in-rafters-necessary_o

https://www.jlconline.com/how-to/framing/are-birdmouths-in-rafters-necessary_o

steveray

SAWHORSE

Those last two pics have zero for thrust connection potential, just so people are aware....

MACV

Registered User

Simpson makes a variable pitch rafter to top plate connector (VPA) that costs about $5. I don't know of any other code compliant method.

fatboy

Administrator

Just remember to cut the birds mouth.........correctly.

MACV

Registered User

If the roof is properly framed, the load at the top plate will be vertical instead of parallel to the rafter pitch.

That is not entirely true...If the roof is properly framed, the load at the top plate will be vertical instead of parallel to the rafter pitch.

With traditional rafter framing, there is always a component of outward thrust. If there wasn't, we would not have the requirements for rafter ties. The use of methods such as birdsmouth notches, rafter ties, etc. are all methods for managing the outward thrust that is intrinsic to the load dispersion of a triangular shape.

It is due to this load dispersion that triangles are the second strongest shape, circles being the strongest.

ADAguy

Registered User

I like the per se comment. I just couldn't find anything saying it has to be there but don't know why you wouldn't put one on the rafter. For download bearing it is the best way to transfer the load. A bevel strip albeit something doesn't transfer the load the same way. Just dealing with someone who likes arguing with the inspector as per your quote Ty

don't you use axes up your way?

my250r11

Sawhorse

Rafter tie would help with the outward thrust. Not sure they will do anything for the downward thrust. Albeit more than not having anything.

The Simpson tie or an engineer would be my opinion.

The Simpson tie or an engineer would be my opinion.

MACV

Registered User

In other words, the horizontal force of a sloping rafter should be resisted by floor/ceiling joists/ties or a ridge beam. When the tie is blew the top p;

I have yet to find a way to edit comments. What I wanted to say is that the horizontal force of the rafter must be neutralized/resisted by either a horizontal tie or a ridge beam so that force should not be an issue at a typical top plate-to-rafter connection (diagrams 1 & 2) but it would be an issue when the horizontal tie is below the top plate (diagram 3) and not otherwise connected to the rafter which is not typical although I do it often in order to increase the height of the exterior wall above the windows.

In any case, a bird's mouth or a metal connector is required.

That is not entirely true...

With traditional rafter framing, there is always a component of outward thrust. If there wasn't, we would not have the requirements for rafter ties. The use of methods such as birdsmouth notches, rafter ties, etc. are all methods for managing the outward thrust that is intrinsic to the load dispersion of a triangular shape.

It is due to this load dispersion that triangles are the second strongest shape, circles being the strongest.

I have yet to find a way to edit comments. What I wanted to say is that the horizontal force of the rafter must be neutralized/resisted by either a horizontal tie or a ridge beam so that force should not be an issue at a typical top plate-to-rafter connection (diagrams 1 & 2) but it would be an issue when the horizontal tie is below the top plate (diagram 3) and not otherwise connected to the rafter which is not typical although I do it often in order to increase the height of the exterior wall above the windows.

In any case, a bird's mouth or a metal connector is required.

steveray

SAWHORSE

Proper rafter ties....collar ties are for uplift on the back side of the roof....Ridge beam does control thrust, if the ridge can't sag, the walls can't bow....

Mr. Inspector

SAWHORSE

Proper rafter ties....collar ties are for uplift on the back side of the roof....Ridge beam does control thrust, if the ridge can't sag, the walls can't bow....

Where ceiling

joists or rafter ties are not provided, the ridge formed by

these rafters shall be supported by a wall or girder designed

in accordance with accepted engineering practice.

A beam is a girder

steveray

SAWHORSE

Correct....As opposed to a ridge board....which does not "support" the rafters per se but a means of connection....

R802.3 Framing details. Rafters shall be framed not more than 11/2-inches (38 mm) offset from each other to ridge board or directly opposite from each other with a gusset plate as a tie. Ridge board shall be not less than 1-inch (25 mm) nominal thickness and not less in depth than the cut end of the rafter.

R802.3 Framing details. Rafters shall be framed not more than 11/2-inches (38 mm) offset from each other to ridge board or directly opposite from each other with a gusset plate as a tie. Ridge board shall be not less than 1-inch (25 mm) nominal thickness and not less in depth than the cut end of the rafter.

alaskajoe,

Is there a ceiling joist being used? you said over a stairway so I assume not, and the span can't be that long, can it?

Also, when a truss is used, typically there is no birds mouth connection to the top plate, metal connectors are used.

Is there a ceiling joist being used? you said over a stairway so I assume not, and the span can't be that long, can it?

Also, when a truss is used, typically there is no birds mouth connection to the top plate, metal connectors are used.