jar546

Forum Coordinator

I have 2 items for this post to discuss. The first is a major pet-peeve and the 2nd is something that I did not know. Let's start with what I did not know:

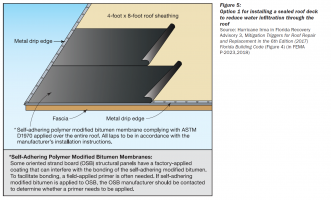

I did not know that some OSB have a factory-applied coating that can interfere with the bonding of self-adhering modified bitumen. In some cases, you have to apply a bonding agent first. This, I did not know. In Florida I really don't see any OSB and I only see plywood on roofs and sometimes for a 2nd floor...floor. That is it. We are all CMU & slab around here. If I were still in Pennsylvania, this would be a really big deal. I am embarrassed to say that I did not know this.

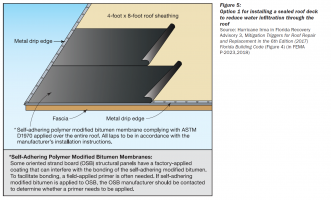

Now for my 30 year pet peeve. If you see the figure below, you will notice a few things:

1) The drip edge and bitumen are installed in 'shingle' fashion.

2) First you install the bottom edge drip edge

3) Then you install the bitumen

4) Finally you install the metal drive edge of the rake end.

There is no other way to do this that makes sense. If it is not installed this way, it is wrong. Wrong, wrong, wrong if it is done any other way.

I did not know that some OSB have a factory-applied coating that can interfere with the bonding of self-adhering modified bitumen. In some cases, you have to apply a bonding agent first. This, I did not know. In Florida I really don't see any OSB and I only see plywood on roofs and sometimes for a 2nd floor...floor. That is it. We are all CMU & slab around here. If I were still in Pennsylvania, this would be a really big deal. I am embarrassed to say that I did not know this.

Now for my 30 year pet peeve. If you see the figure below, you will notice a few things:

1) The drip edge and bitumen are installed in 'shingle' fashion.

2) First you install the bottom edge drip edge

3) Then you install the bitumen

4) Finally you install the metal drive edge of the rake end.

There is no other way to do this that makes sense. If it is not installed this way, it is wrong. Wrong, wrong, wrong if it is done any other way.