jar546

Forum Coordinator

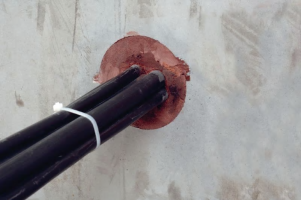

I came across this situation in a school where FMC conduit was penetrating a fire rated wall separating a classroom from the corridor.

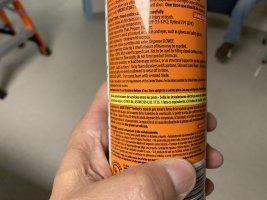

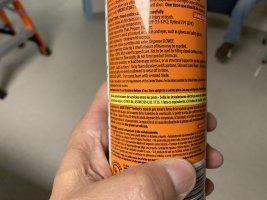

whenever I see orange foam on a commercial job site I sort of cringe and start hunting for it. I read the ICC – ES report for this and it is basically for blocking in wood frame construction on residential structures.

what are your thoughts?

whenever I see orange foam on a commercial job site I sort of cringe and start hunting for it. I read the ICC – ES report for this and it is basically for blocking in wood frame construction on residential structures.

what are your thoughts?