Easttndeveloper

Registered User

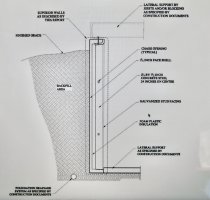

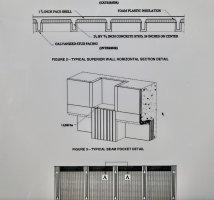

Hi, im new to the forum. I recently had superior walls of east tn install some walls for me on a development we are starting and im less than pleased and looking for some guidance, they installed the walls and in 2 different locations installed them inside out, they have the stud side facing the backfill and the exterior side facing the interior living space. Now i hired a 3rd party engineer that stated that this is the incorrect method and the walls will fail because the rebar is now closest to backfill instead of furthest from backfill. We cut into the wall to verify and there is only 1 rebar per stud and it most definitely is closest to backfill so all the backfill which is 9 ft of gravel because it is where the garage is located will be pushing directly against the sheathing which is only 1 3/4 thick concrete. The manufacturer is saying the walls are ok and will not help us in anyway to correct the issue. Thanks in advance.