We have a residential builder in our jurisdiction who frames his roofs the old way with rafters, instead of using trusses like everyone else. So, when we inspect his projects, one of the main things we look at is the bearing of the rafters on the top plate.

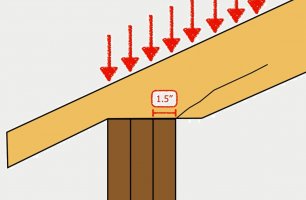

So, we have written him up multiple times for having the rafters bear on the toe of the cut rather than the heel of the cut (see pictures). By cutting/notching the rafters this way, he reduces the depth of the rafters, allowing the rafter to split along the grain and greatly reducing the span of the rafters. This issue could be solved by using longer rafters and raising the roof a few inches to bear on the heel of the cut, or by changing the pitch of the roof slightly to bear on the heel of the cut, but the contractor does not like either option for complicated reasons.

The structural engineer he hired is telling him that cutting/notching in this way is a non-issue, which I can accept on a case-by-case basis, but I am not comfortable using that as a blanket rule of thumb.

Is there any way the pictures I am showing are a prescriptive method of rafter bearing or cutting/notching? How do other jurisdictions handle this?

So, we have written him up multiple times for having the rafters bear on the toe of the cut rather than the heel of the cut (see pictures). By cutting/notching the rafters this way, he reduces the depth of the rafters, allowing the rafter to split along the grain and greatly reducing the span of the rafters. This issue could be solved by using longer rafters and raising the roof a few inches to bear on the heel of the cut, or by changing the pitch of the roof slightly to bear on the heel of the cut, but the contractor does not like either option for complicated reasons.

The structural engineer he hired is telling him that cutting/notching in this way is a non-issue, which I can accept on a case-by-case basis, but I am not comfortable using that as a blanket rule of thumb.

Is there any way the pictures I am showing are a prescriptive method of rafter bearing or cutting/notching? How do other jurisdictions handle this?