StuartL

REGISTERED

We're installing a new bathroom on the second floor of our house, which has 2x8 floor joists. The 3" toilet drain does not need to cross through any joists, but the 1.5" drain pipe servicing the tub and sink needs to cross multiple joists (roughly 8' run). The limitations for our build and the Ontario Building code...

Is there a standard solution for this? E.g. thin walled pipe, or laminating joists to allow larger holes?

Or, is there something like these products that are engineered for use in Ontario?

www.metwood.com

www.metwood.com

joistrepair.com

joistrepair.com

We are trying to do this on a budget, so would like to avoid having to get an engineer involved.

Thanks in advance!

- 1.5" is required for sinks and showers with one head

- 1.5" pipe seems to always have a 1.9" outer diameter, which would mean drilling a 2" hole in each joist

- you can only cut a hole 1/4 the depth of the joist... 7.25/4 is roughly 1.8"

Is there a standard solution for this? E.g. thin walled pipe, or laminating joists to allow larger holes?

Or, is there something like these products that are engineered for use in Ontario?

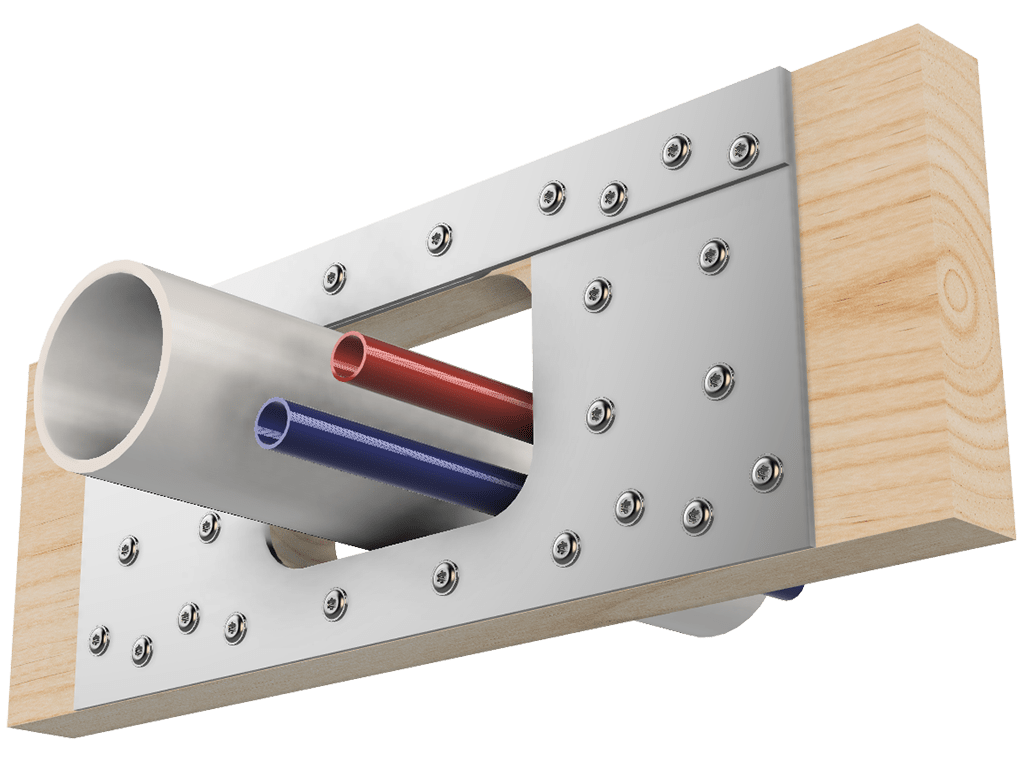

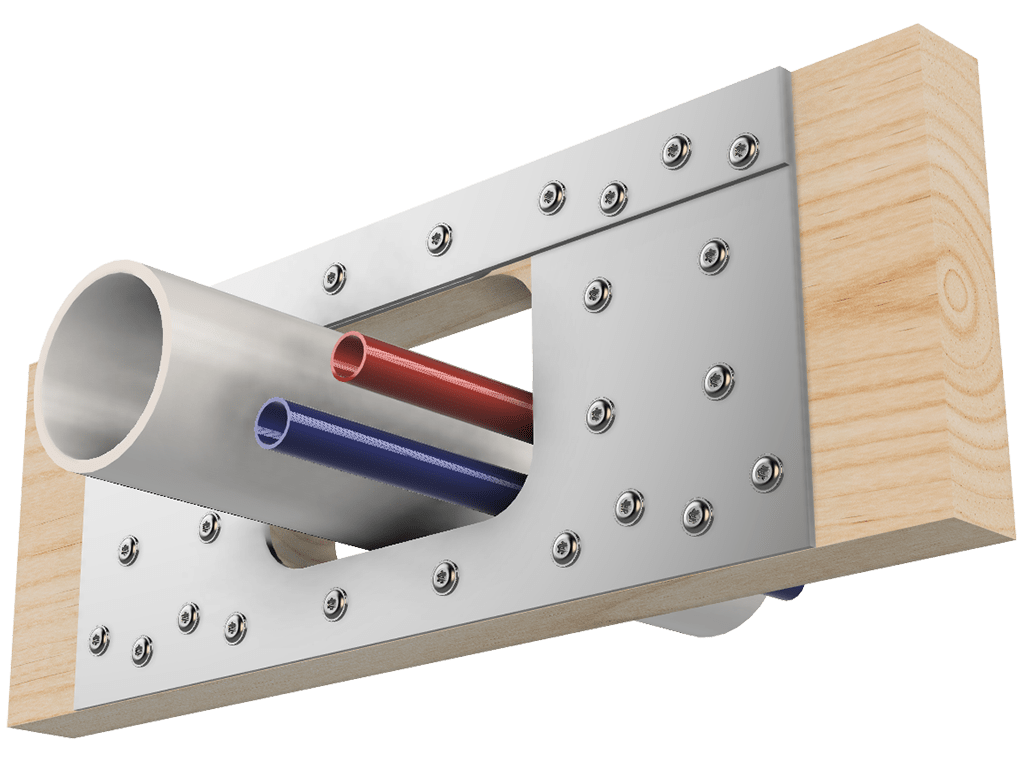

Joist Repair Hole Reinforcer 2810HR By Metwood

The 2810HR Joist Reinforcer allows the placement of a 6” diameter hole in a 2x10 or 2x12 wood joist and a 4” diameter hole in a 2x8.

2x8 HR Floor Joist Hole Repair Kit for reinforcing joist or truss holes, route utilities right through floor joists

The 2x8 HR Joist Hole Reinforcer is the perfect joist repair kit for repairing or restoring the strength of floor joists that have been compromised due to holes, cuts, or or even cracks. The 2x8 HR can handle holes up to 4" diameter in 2" x 8" joists when holes have been cut that are larger than...

We are trying to do this on a budget, so would like to avoid having to get an engineer involved.

Thanks in advance!