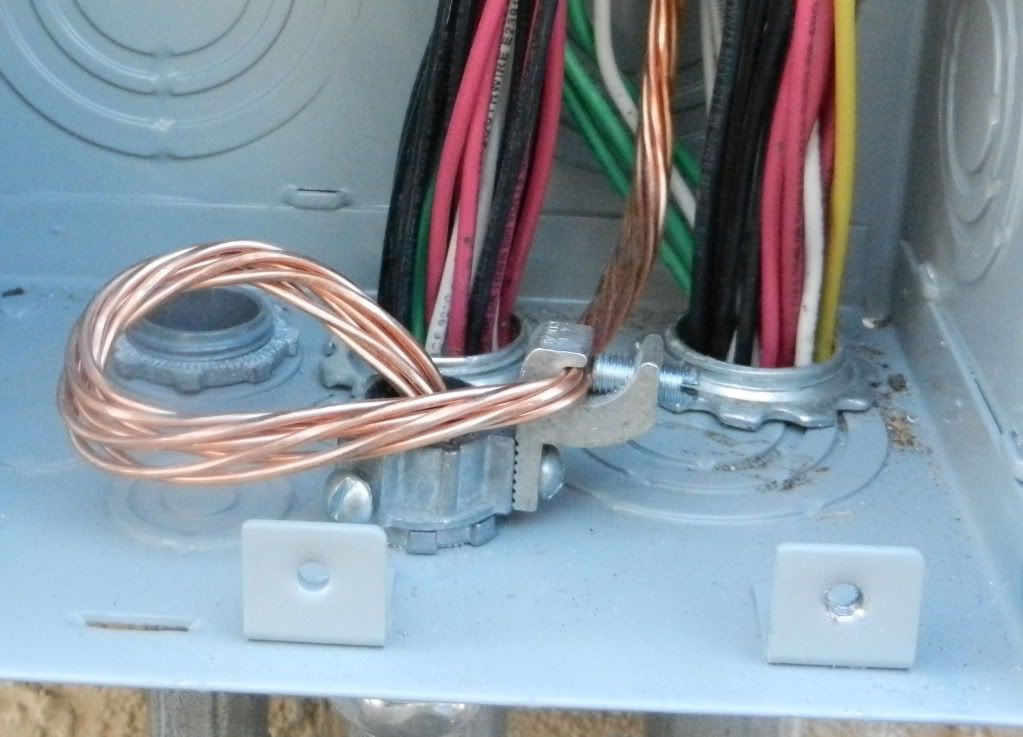

not using an irreversible connections on a gec if a splice is necessary, unprotected gec's from panel to earth connection, no gec in foundation when called for steel pre pour inspection, romex unprotected or to close to attic access scuttle holes, romex nailed down the stud closer than 1-1/4 inches from face of stud, improper citrcuit breaker sizing on furnace or ac compressor (usually too large), wrong kind of disconnect for attic installed gas fired furnace with motor over 1/8 hp, no gfci in basement, improper spacing of counter top receptacle outlets, outlets in wood framed structures (kithcens) that don't extend out to the face of the tile (lots of tradespeople don't realize that a tiled wall (in a wood framed house) is not the same as "non combustible construction" per the NEC requierements). box fill, too much wire in a gutter , not ensureing a good contact with lugs (scrape the paint off the boxes and cans per the code, grounding locknuts ( why don't folks understand or learn the difference between a grounding locknut and a heavy duty lock nut, huge difference) improper fan boxes, no ground screws in metal boxes, improperly identified grounded conductors, too many bends in a single run of pipe with no pull points, improper wire bending space in panels, improperly sta

rapped or unsupported conduit, installing pvc conduit if a footing section, poor workmanship in general, improper use of materials where not allowed by code