Keystone

SAWHORSE

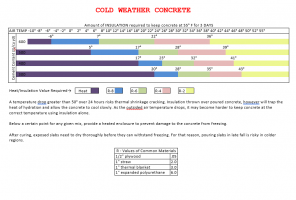

Assumed, cold weather concrete protection, below 40*F, equals blankets or similar approved. Without sources for heat.

Given, ACI 306, 28*F and rising to pour.

Comment, Being ACI calls for the minimum temperature to be 28*F, would it be wrong to interpret the temperature shall remain above 28*F after the pour, say overnight and successive days?

If you believe it’s wrong, why? Can anyone cite a section of ACI that states otherwise?

NOTE, I see ACI offers a commentary on structural concrete but nothing for Cold Weather Concrete.

Given, ACI 306, 28*F and rising to pour.

Comment, Being ACI calls for the minimum temperature to be 28*F, would it be wrong to interpret the temperature shall remain above 28*F after the pour, say overnight and successive days?

If you believe it’s wrong, why? Can anyone cite a section of ACI that states otherwise?

NOTE, I see ACI offers a commentary on structural concrete but nothing for Cold Weather Concrete.

ACI CODE-318-19(22): Building Code Requirements for Structural Concrete and Commentary (Reapproved 2022)

The “Building Code Requirements for Structural Concrete” (“Code”) provides minimum requirements for the materials, design, and detailing of structural concrete

www.concrete.org