andyanderson91

Registered User

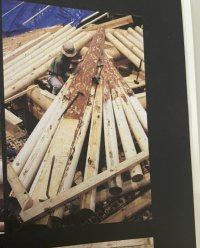

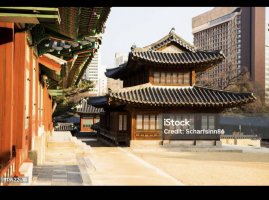

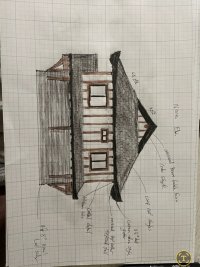

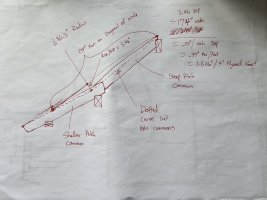

I plan to build a curved Dutch hip style roof.

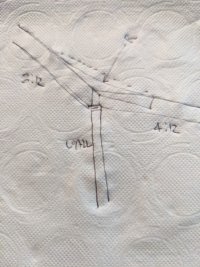

For the roof decking, if the radius (using a circle for it's gradual sweep) is large enough? Say a 264' radius as I've roughly calculated with the equation of a circle set to the actual width or run of the roof, and the rise superimposed to copy other designs. Question, will typically 1/2" plywood bend that little bit without any thought given by the building inspector? How much rise/bend along an 8' sheet of plywood if gradual as seen in a typical circle's radius, is too much for the fasteners to handle or the plywood itself?

I'm aware it will have to be engineered regardless since it will not be a prescriptive roof design. Thought for a moment if it were a gable roof and the meat in the rafter left after cutting a curve, met the prescriptive requirement, would the plywood bend cancel out the ability to build that curved rafter prescriptive?

For the roof decking, if the radius (using a circle for it's gradual sweep) is large enough? Say a 264' radius as I've roughly calculated with the equation of a circle set to the actual width or run of the roof, and the rise superimposed to copy other designs. Question, will typically 1/2" plywood bend that little bit without any thought given by the building inspector? How much rise/bend along an 8' sheet of plywood if gradual as seen in a typical circle's radius, is too much for the fasteners to handle or the plywood itself?

I'm aware it will have to be engineered regardless since it will not be a prescriptive roof design. Thought for a moment if it were a gable roof and the meat in the rafter left after cutting a curve, met the prescriptive requirement, would the plywood bend cancel out the ability to build that curved rafter prescriptive?