Ryan Schultz

SAWHORSE

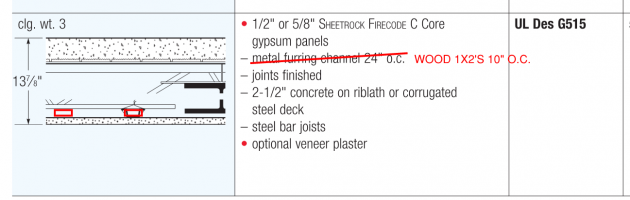

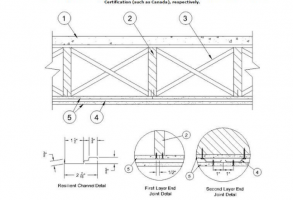

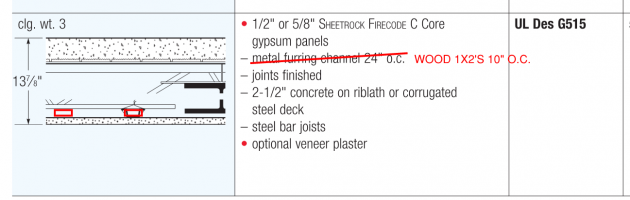

I have an existing floor that is very similar to a 2hr UL G515 floor assembly. The only difference is instead of metal furring, there is Wood 1x2's - 10" o.c.

How do a determine the hourly rating of this floor? I know about chapter 721 and 722, but what I can gather there's no area that talks about wood furring.

How do a determine the hourly rating of this floor? I know about chapter 721 and 722, but what I can gather there's no area that talks about wood furring.