jar546

CBO

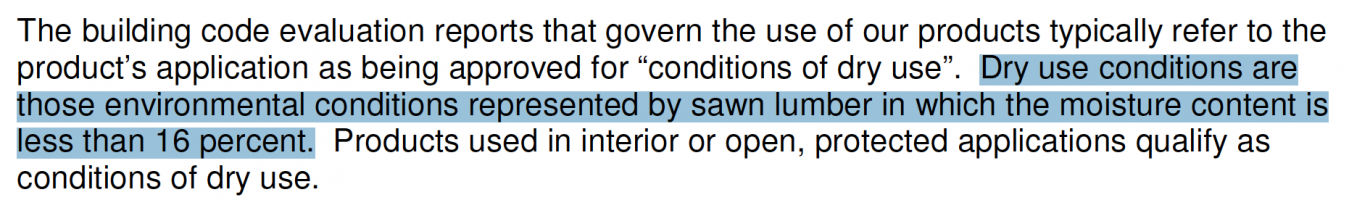

I was just at the New Jersey Motorsports Park outside of Millville, NJ, and noticed the following that made me think. To get out of the rain, I was standing under a deck on a heavy steel frame that was self supporting. It was not attached to the structure it served. The top of the deck was waterproofed, but all of the joists on the steel frame were engineered wood I-Joists. I did not notice any water damage or leaks onto the I-Joists but it made me wonder if these I-joists are even rated or designed to be used in this type of environment.

My initial answer is going to be no, they are not and I am wondering how this was approved. Does anyone have experience with the use of engineered wood I-joists used on an exterior-only project? I forgot to take a picture.

My initial answer is going to be no, they are not and I am wondering how this was approved. Does anyone have experience with the use of engineered wood I-joists used on an exterior-only project? I forgot to take a picture.