jar546

CBO

It's been getting a little old arguing the differences between these over the years, so I thought I would put this together to see if this helps to clarify a few things. Let's start with definitions and meanings. I am using the 2023 NEC, technically known as the NFPA 70.

Grounded (Grounding).

Connected (connecting) to ground or to a conductive body that extends the ground connection.

Ground.

The earth

Bonded (Bonding).

Connected to establish electrical continuity and conductivity.

Bonding Conductor or Jumper.

A reliable conductor to ensure the required electrical conductivity between metal parts required to be electrically connected.

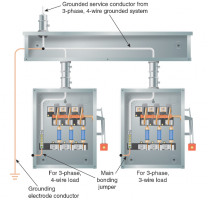

Either of the two terms bonding conductor or bonding jumper may be used. The term bonding jumper is sometimes interpreted to mean a short conductor, although some bonding jumpers may be several feet in length. The primary purpose of a bonding conductor or jumper is to ensure electrical conductivity between two conductive bodies, such as between a box and a metal raceway. Bonding jumpers are particularly important where a box has either concentric- or eccentric-type knockouts. These knockouts can impair the electrical conductivity between metal parts and may actually introduce unnecessary impedance into the grounding path.

Bonding Jumper, Equipment.

The connection between two or more portions of the equipment grounding conductor.

Equipment bonding jumpers ensure that an effective ground-fault current path is not compromised by an interruption in mechanical or electrical continuity. For example, conduits entering an open-bottom switchboard are usually not mechanically connected to the switchboard. Expansion fittings may not provide electrical continuity because they are loosely joined raceways. Bonding jumpers are necessary in order to provide electrical continuity.

Essentially, the purpose of grounding is to connect electrical systems to the earth. The purpose of bonding is to connect electrical equipment and components. The two are integral to each,....well, for the most part. You need bonding to have grounding.

250.4(A)(1) Electrical System Grounding.

Electrical systems that are grounded shall be connected to earth in a manner that will limit the voltage imposed by lightning, line surges, or unintentional contact with higher-voltage lines and that will stabilize the voltage to earth during normal operation.

250.4(A)(3) Bonding of Electrical Equipment.

Normally non–current-carrying conductive materials enclosing electrical conductors or equipment, or forming part of such equipment, shall be connected together and to the electrical supply source in a manner that establishes an effective ground-fault current path.

Grounding is to stabilize a system by establishing a path to ground, the same ground the utility uses when it generates power. This helps to stabilize voltages during lightning events, surges, or short circuits with power lines. Bonding helps to facilitate the operation of overcurrent protection devices (OCPD) such as fuses and circuit breakers during short circuit events.

I hope this helps.

Grounded (Grounding).

Connected (connecting) to ground or to a conductive body that extends the ground connection.

Ground.

The earth

Bonded (Bonding).

Connected to establish electrical continuity and conductivity.

Bonding Conductor or Jumper.

A reliable conductor to ensure the required electrical conductivity between metal parts required to be electrically connected.

Either of the two terms bonding conductor or bonding jumper may be used. The term bonding jumper is sometimes interpreted to mean a short conductor, although some bonding jumpers may be several feet in length. The primary purpose of a bonding conductor or jumper is to ensure electrical conductivity between two conductive bodies, such as between a box and a metal raceway. Bonding jumpers are particularly important where a box has either concentric- or eccentric-type knockouts. These knockouts can impair the electrical conductivity between metal parts and may actually introduce unnecessary impedance into the grounding path.

Bonding Jumper, Equipment.

The connection between two or more portions of the equipment grounding conductor.

Equipment bonding jumpers ensure that an effective ground-fault current path is not compromised by an interruption in mechanical or electrical continuity. For example, conduits entering an open-bottom switchboard are usually not mechanically connected to the switchboard. Expansion fittings may not provide electrical continuity because they are loosely joined raceways. Bonding jumpers are necessary in order to provide electrical continuity.

Essentially, the purpose of grounding is to connect electrical systems to the earth. The purpose of bonding is to connect electrical equipment and components. The two are integral to each,....well, for the most part. You need bonding to have grounding.

250.4(A)(1) Electrical System Grounding.

Electrical systems that are grounded shall be connected to earth in a manner that will limit the voltage imposed by lightning, line surges, or unintentional contact with higher-voltage lines and that will stabilize the voltage to earth during normal operation.

250.4(A)(3) Bonding of Electrical Equipment.

Normally non–current-carrying conductive materials enclosing electrical conductors or equipment, or forming part of such equipment, shall be connected together and to the electrical supply source in a manner that establishes an effective ground-fault current path.

Grounding is to stabilize a system by establishing a path to ground, the same ground the utility uses when it generates power. This helps to stabilize voltages during lightning events, surges, or short circuits with power lines. Bonding helps to facilitate the operation of overcurrent protection devices (OCPD) such as fuses and circuit breakers during short circuit events.

I hope this helps.