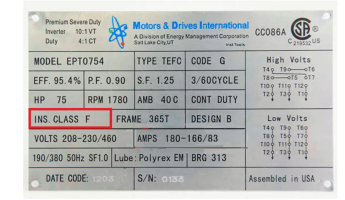

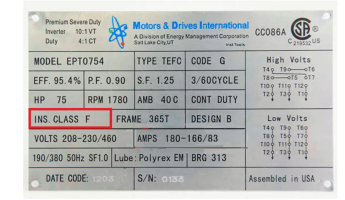

Motor nameplates provide essential information that ensures motors are installed and operated safely and in compliance with codes. As an inspector, understanding this information is crucial for verifying installations.

- Manufacturer & Model Number

- Purpose: Identifies the motor for reference and verification.

- Inspection Tip: Ensure the motor is listed and labeled by a recognized testing laboratory.

- Voltage (V)

- Purpose: Indicates the operating voltage.

- Inspection Tip: Verify that the motor's voltage rating matches the supply voltage.

- Full Load Amperage (FLA)

- Purpose: Shows the current drawn at full load.

- Inspection Tip: Use this to confirm correct sizing of conductors and overcurrent protection devices.

- Frequency (Hz)

- Purpose: Specifies the operating frequency.

- Inspection Tip: Ensure compatibility with the system frequency (typically 60 Hz in North America).

- Phase

- Purpose: Indicates single-phase or three-phase operation.

- Inspection Tip: Confirm that the motor's phase matches the supply.

- Horsepower (HP)

- Purpose: Denotes the motor's output power.

- Inspection Tip: Use this to verify appropriate application and load handling.

- Speed (RPM)

- Purpose: Shows the motor's rotational speed.

- Inspection Tip: Ensure the speed is suitable for the connected equipment.

- Service Factor (SF)

- Purpose: Indicates the motor's overload capacity.

- Inspection Tip: Recognize that a higher SF allows for occasional overloads; ensure it's not used continuously beyond its rating.

- Insulation Class

- Purpose: Defines the thermal tolerance of the motor's insulation.

- Inspection Tip: Confirm that the motor's insulation class is appropriate for the operating environment.

- Enclosure Type (e.g., TEFC, ODP)

- Purpose: Describes the motor's protection against environmental factors.

- Inspection Tip: Ensure the enclosure type suits the installation location (e.g., TEFC for dusty environments).

- Ambient Temperature Rating

- Purpose: Specifies the maximum ambient temperature for safe operation.

- Inspection Tip: Verify that the motor is suitable for the ambient conditions of the installation site.

- Duty Cycle

- Purpose: Indicates how long the motor can operate under specific conditions.

- Inspection Tip: Ensure the motor's duty rating aligns with its intended use.

- Code Letter

- Purpose: Provides information on the motor's starting current.

- Inspection Tip: Use this to assess the impact on the electrical system during startup.

- Design Letter

- Purpose: Defines the motor's torque and starting characteristics.

- Inspection Tip: Confirm that the motor's design is appropriate for the application.

- Efficiency

- Purpose: Shows how effectively the motor converts electrical energy to mechanical energy.

- Inspection Tip: Higher efficiency motors reduce energy costs and heat generation.

Here's an example of a typical motor nameplate: