Kevin

REGISTERED

I had a preliminary code review with AHJ for a project I'm working on and the reviewer raised a concern about insulated metal panels. They thought the exterior walls should be fire rated with a symmetrical assembly that is resistant from both sides.

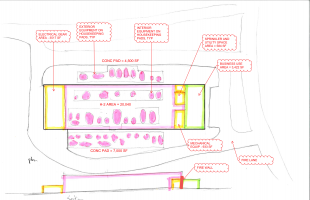

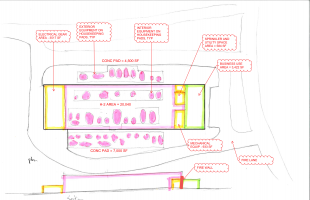

The building will be large, low occupancy and about 200' from any nearby building. I've been able to get the allowable area to work out with a frontage increase using Type 1B construction. The building will be steel framed and the largest volume only needs to be semi-heated since it's all equipment. I don't see anything in the code telling me that the exterior walls have to be fire rated per IBC 601 and IBC 705.5.

The large volume (H-2 use) will be about 45' tall and "book-ended" by utility spaces on each end . One end will have electric with a 2 hour fire rated separation between it and the H-2 use. This end will be ~ 15' tall. and the other end will be incidental space with non-hazardous mechanical equipment, sprinkler riser and additional utility space. The incidental end will have another 2 hour fire rated separation between it and small business occupancy for the people that run the plant. The business end will also be ~ 15' tall. I was planning on CMU walls to achieve the 2 hour separation at each end. I could extend the cmu walls 30" above the lower roofs to meet 706.6.1 stepped buildings, but I don't think that is necessary per IBC 707.5 Continuity for Fire Barriers.

I found a memo from Centria that explains how their foam plastic insulated metal panels meet code since they meet special approval. As stated above this was a preliminary review, so the AHJ isn't that familiar yet w/ the project and all the specifics. Is there something I'm missing. They are of the mindset that this has to have tilt-up concrete panels and I just don't see it in the code. We will be calling for all of the steel structure to have Spray Applied Fireproofing or Intumescent Paint, perhaps they are thinking of IBC 704.2 Column Protection?

I'd love to hear some thoughts on this, I find this site is more helpful sometimes than calling ICC. Thank you!

I've found a few memo's from IMP manufacturers that explain how their IMP's meet chapter 26.

The building will be large, low occupancy and about 200' from any nearby building. I've been able to get the allowable area to work out with a frontage increase using Type 1B construction. The building will be steel framed and the largest volume only needs to be semi-heated since it's all equipment. I don't see anything in the code telling me that the exterior walls have to be fire rated per IBC 601 and IBC 705.5.

The large volume (H-2 use) will be about 45' tall and "book-ended" by utility spaces on each end . One end will have electric with a 2 hour fire rated separation between it and the H-2 use. This end will be ~ 15' tall. and the other end will be incidental space with non-hazardous mechanical equipment, sprinkler riser and additional utility space. The incidental end will have another 2 hour fire rated separation between it and small business occupancy for the people that run the plant. The business end will also be ~ 15' tall. I was planning on CMU walls to achieve the 2 hour separation at each end. I could extend the cmu walls 30" above the lower roofs to meet 706.6.1 stepped buildings, but I don't think that is necessary per IBC 707.5 Continuity for Fire Barriers.

I found a memo from Centria that explains how their foam plastic insulated metal panels meet code since they meet special approval. As stated above this was a preliminary review, so the AHJ isn't that familiar yet w/ the project and all the specifics. Is there something I'm missing. They are of the mindset that this has to have tilt-up concrete panels and I just don't see it in the code. We will be calling for all of the steel structure to have Spray Applied Fireproofing or Intumescent Paint, perhaps they are thinking of IBC 704.2 Column Protection?

I'd love to hear some thoughts on this, I find this site is more helpful sometimes than calling ICC. Thank you!

I've found a few memo's from IMP manufacturers that explain how their IMP's meet chapter 26.