jar546

CBO

Does it matter where I tap the load side of a feeder?

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

The tap shall be permitted at any point on the load side of the feeder overcurrent protective device.Yes, it has to be within a given distance of the OCPD supplied by the feeder tap, as per the section of 240.21(B) under which the tap is permitted.

Cheers, Wayne

The above is open to misinterpretation. We've got a few different variables here--location of the feeder OCPD, location of the OCPD supplied by the tap, and location of the tap.The tap shall be permitted at any point on the load side of the feeder overcurrent protective device.

Yes, I agree. The discussion was never about the length or size of the tap conductors themselves.It's true that generically there's no restriction on where the tap can be on the load side of the feeder OCPD, it can even be on the feeder OCPD load side lugs.

Yet clearly the location of the tap is one of the variables that determines the length of the tap conductors, and as the length of the tap conductors is typically constrained, that translates into a possible constraint on the tap location. It's simple geometry.Yes, I agree. The discussion was never about the length or size of the tap conductors themselves.

Turns out it was geography that I would never have to use. Who knew?It's simple geometry.

Please give us a specific example of where the location of the tap to a feeder is limited in location. I will provide an example and you can explain where the tap location is limited to.Yet clearly the location of the tap is one of the variables that determines the length of the tap conductors, and as the length of the tap conductors is typically constrained, that translates into a possible constraint on the tap location. It's simple geometry.

Cheers, Wayne

OK I'll draw something up, but first let me just put my point this way:Please give us a specific example of where the location of the tap to a feeder is limited in location.

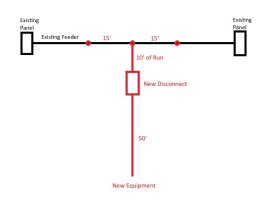

Here's my fairly basic drawing. The existing panels and feeder are in black. The location of the new equipment is fixed by the customer's needs. The location of the new disconnect is fixed by needing to be in line of sight of the new equipment, which per the NEC definition limits it to 50' away. The customer doesn't want a second disconnect.OK I'll draw something up

Oh, I forgot to mention one more customer requirement, no diagonal conductor conductor runs. [That's just to keep the math simpler.] The "10' of run" figure already includes any necessary contribution from the vertical dimension not shown in the drawing.Here's my fairly basic drawing.

Correction, the feeder tap rules are in 240.21(B), not 240.21(C).240.21(C)(1), the 10' tap rule . . .

240.21(C)(2), the 25' tap rule . . .

240.21(C)(5), the outdoor tap rule