Sifu

SAWHORSE

- Joined

- Sep 3, 2011

- Messages

- 3,382

Is there a diversity of demand (or some similar method) that is or can be used when calculating the maximum DFU's for a branch drain and a building drain? I have a proposal for 28 commercial washers installed in two bulkheads of 14 each. Each machine discharges 45gpm, which is converted to 90 DFU's per IPC 709.3. Each bulkhead is drained by a single branch drain, both of which converge into a single building drain. By my estimation each branch would be required to be 8" and the building drain would be required to be 12".

This seems really high, so maybe my reasoning is flawed. The proposal is for 4" branch drains, and a 4" building drain. This seems really low.

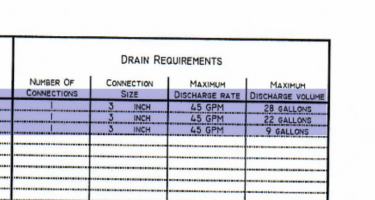

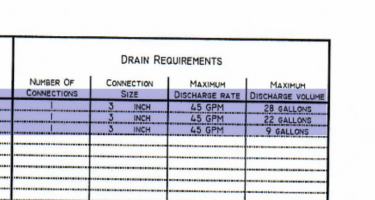

709.3 says "where discharges to a waste receptor or to a drainage system are only known" in GPM, then you calulate it at 2 DFU's per 1 gpm. Per t709.1, each would only have 3 DFU's. The MFR has only provided the chart below, showing discharges in gpm. I must be reading something wrong.

All guidance is appreciated.

This seems really high, so maybe my reasoning is flawed. The proposal is for 4" branch drains, and a 4" building drain. This seems really low.

709.3 says "where discharges to a waste receptor or to a drainage system are only known" in GPM, then you calulate it at 2 DFU's per 1 gpm. Per t709.1, each would only have 3 DFU's. The MFR has only provided the chart below, showing discharges in gpm. I must be reading something wrong.

All guidance is appreciated.

Last edited: