I am not an expert by any stretch and it is difficult at best to apply all of the systems within systems concerning the totality of mechanical systems without a basic practical engineering point of view IMHO. That being said, I think the mechanical code (chapter 4 & 5) really is about checking of minimum numbers as they apply to ventilation/exhaust air or perhaps better stated, ventilation & exhaust systems functionality, nothing to do with human comfort.

Human comfort in a kitchen really gets blown away by all the exchange rates that intermingle with the kitchen exhaust system(s) IMO.

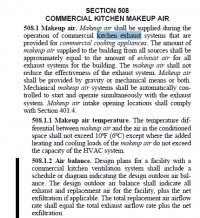

From a conservation approach (IECC), the intent IMO, is to abandon the energy sucking circuit venting of commercial hoods which cause all kinds of imbalances to the positive or negative pressure differences by having equipment running 24/7 without direct control intervention. Remember positive or negative pressure is atmospheric pressure. In the case of hoods being slightly negative, the idea is to keep the air in the room, hence not smelling your steak cooking a 100 feet away from the kitchen, is an improper design. The opposite, positive pressure, think hospital room keeping unwanted air out.

Coming back to the logic of providing the make up air to the kitchen hood from other spaces (RTU's. HVAC, MAU's, etc.) is not a bad idea, slightly negative at the hood(s). The energy savings are enormous versa all of that human comfort air being sucked out by the exhaust with excessive negative pressure.

But it is always a challenge capturing the exact CFM's required (the total rate of ventilation air) when unknowns exist without confirmed compliance with the air barrier requirements for exfiltration/infiltration accounted for, hence the requirements to meet the leakage rates.

The reason for opining, is from a project I am reviewing with under floor supply plenums. OMAU's, RTU's & kitchen hoods and not accounting for types of exhaust fans. i.e. bathroom, IT closets & etc..

Speaking off numbers game. Does anyone know of a site that provides some free training on mechanical systems, that kind of explains the madness. The code and commentary only go so far in knowledge....

Thanks

Bryant