dhengr, Something will kindle each time. I appreciate engineers being here to catch me. No disrespect intended, make heat not smoke, you could have posted that bending formula in jobsavers thread and explained it yourself, I wait hoping you guys will do some teaching. The crown post under the beam looks fine. The load needs to be quantified and check the bearing area on top of the header to make sure it is within the allowable side grain compression (crushing) strength of the header, make sure the post is not driven into the header. I agree that on a short, heavily loaded beam horizontal shear often controls rather than bending strength. This is a set of pics I had on my computer to demonstrate horizontal shear in a uniformly loaded beam. Notice the vertical lines after the uniform load is applied.

Center

End

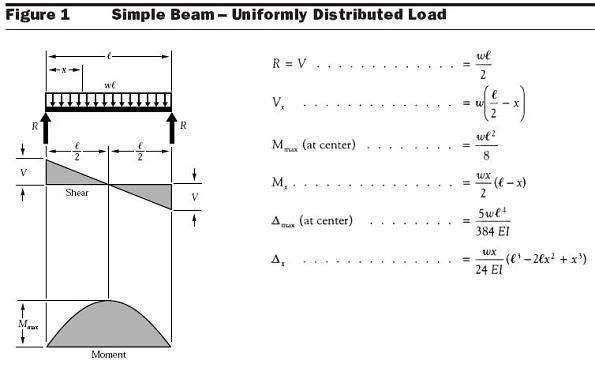

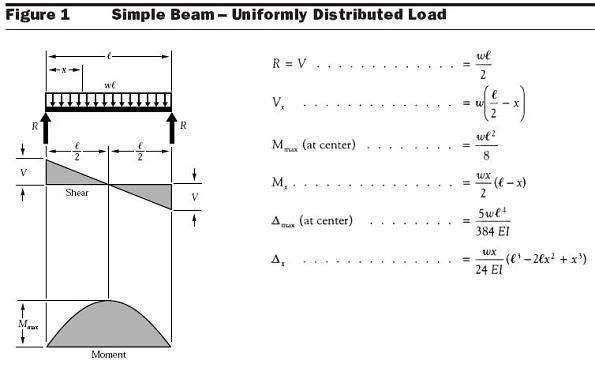

There is zero horizontal shear in the center and maximum shear force at the ends of a beam. Maximum bending moment occurs where the magnitude of shear passes through zero. Here is the graphic for a uniformly loaded beam, notice where shear passes through zero and where the maximum bending moment occurs. Look back at the pics above, same dang thing.

Stack all three boxes in the middle of the beam, see how the bending moment would be doubled? Always check deflection. Then check the jack to header bearing area for crushing. After that the built up column has a couple of issues. It is recieving an axial load down its' length from above while simultaneously getting a bending load from wind. What dhengr called a beam/column, you'll find in the NDS under "combined bending and axial loading". To illustrate this, take a slender stick like a yardstick, stand it on the floor and push down on it. It will accept a certain amount of load, the roof gravity load. Now while doing that push on the side of it, the wind, it just got a whole lot weaker didn't it? The more vertical, axial, load the less bending, wind, load the post can handle... and vice versa. One tall slender post is doing two things, the analysis weighs and balances that interrelationship between the two loads to make sure that the column is capable of handling both loads safely. (For you old engineers this changed in the '05 NDS. There is a new design value, Emin, to be used with columns, you can download the Supplement of Design Values on the awc.org site under "publications". It will not really change your results but is the "proper" way to do the math using an "allowable" Emin rather than an absolute value for E.)I've reinforced these columns by making them deeper or with steel sandwiched in them to form a flitch plate. I've also run a flatways "plant shelf" beam horizontally across the header between the window levels and secured it to the sidewalls, the reaction is directed through and down them. As dhengr pointed out, either way the ends are beam reactions that need to be secured as such. Since this was engineered, it points out why I as a carpenter have tried to pick up a bit of engineering along the way, more eyes.

View attachment 360

View attachment 361

View attachment 362

View attachment 363

View attachment 360

View attachment 361

View attachment 362

View attachment 363

/monthly_2011_01/shear1.jpg.2b5669a0f5d489358d9c52625745b5cb.jpg

/monthly_2011_01/shear2.jpg.9cda2f4a2d296f3952f5692c389fd2f8.jpg

/monthly_2011_01/shearmid.jpg.b39377f69f675f704f8e107db0481b06.jpg

/monthly_2011_01/shearend.jpg.9f8afc02eda94fe4105049b5dae4d401.jpg