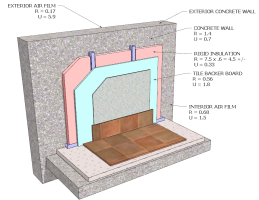

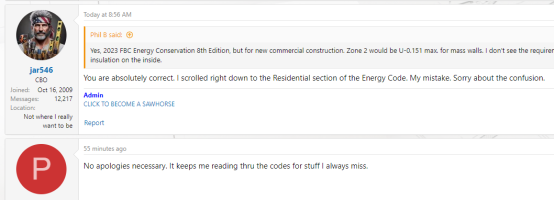

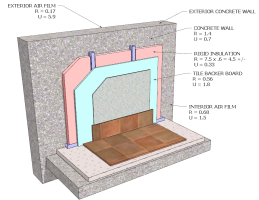

I may need to insulate an exterior concrete wall on the interior side and have always been a little confused on the difference between R-Value approach versus the U-Value approach. For example, the R-Value requirement for an exterior Mass wall in Climate Zone 2 is R-5.7ci. The R-values in the wall below add up to approximately 7.3. This wouldn't comply because the insulation is not continuous. However, if you look at the wall based on the U-value method, the U-value would be 0.137 which would comply because it is below the maximum 0.151 allowed.

This seems to be contradictory. Am I looking at things wrong, or simply misunderstanding the code?

This seems to be contradictory. Am I looking at things wrong, or simply misunderstanding the code?