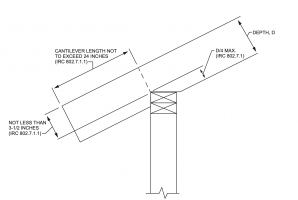

The AF&PA NDS says use a distance of D from the support. The NDS does not address the situation where the beam is installed on a slope.

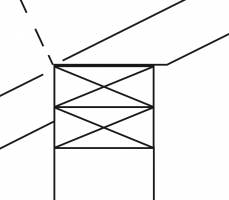

Using the methodology proposed would underestimate the shear when there is a steep slope.. Check the shear when the slope is 1 to 1. Since the slope is 45 degrees the line would never intersect with the top of the beam.

I would recommend caution when dealing with a slopped roof.

Using the methodology proposed would underestimate the shear when there is a steep slope.. Check the shear when the slope is 1 to 1. Since the slope is 45 degrees the line would never intersect with the top of the beam.

I would recommend caution when dealing with a slopped roof.