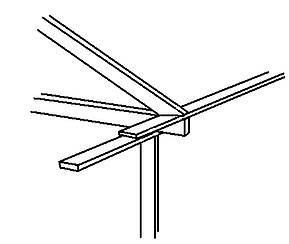

This situation is a continual issue for me. The codes require a "rafter tie", the continuous member tying rafters together to counteract rafter thrust. The IRC and the commentary are clear and direct with no apparent leeway. Unfortunately, few structures are built in a manner that would make it possible or practical to install a rafter tie in the manner the code requires. Installing the "code approved" rafter tie entails setting the rafter and the ceiling joist side by side on the supporting member, which leaves little room for the insulation required by the energy code. (most houses around here are still stick-framed, hips and built with raised heel heights which makes the traditional rafter tie impossible) The WFCM does allow the rafter tie to be moved up in the roof, as long as it remains in the bottom 1/3 of the attic space but again often times this is not possible or practical. I just don't think the code had the size and scope of the houses today in mind a lot of the time. Bonus rooms are a real problem for the builders around here. I am a firm believer in the validity of the rafter tie, especially after seeing many of the houses around here being built without them and seeing first hand what happens. I do wish the code could update itself with some alternate methods of compliance such as the one pictured. I have seen this very detail in a JLC engineering article and have allowed it a few times. In my humble opinion it does comply with the code. As for the insulation......I would rather see good structure with a little compromised insulation than good insulation with a little compromised structure! All in all, trusses would be easier to inspect and given the methods I see better.