-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

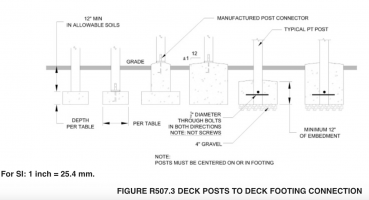

Through Bolt Sizes for Deck Footers

- Thread starter jar546

- Start date

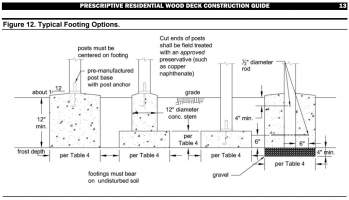

DCA6 specifies a 6" extension of the 1/2" rod.

https://awc.org/wp-content/uploads/2022/02/AWC-DCA62015-DeckGuide-1804.pdf

https://awc.org/wp-content/uploads/2022/02/AWC-DCA62015-DeckGuide-1804.pdf

jar546

CBO

Yes, which is why I don't know why it is not in the IRC. I just mentioned the DCA6 in another recent thread I just started.

How critical is the length of the bolt that sticks out of the post? The reason for the bolt is to lock the post to the concrete block. Is there a need for two bolts?

jar546

CBO

I've had #6 rebar specified at 18" in length in both directions so they would fit into a 24" round hold through a 6x6. This is what the engineers wantedHow critical is the length of the bolt that sticks out of the post? The reason for the bolt is to lock the post to the concrete block. Is there a need for two bolts?

jar546

CBO

Placing rebar in both directions in a concrete-set wood post helps it handle loads coming from any angle, not just straight up and down. It's like creating a strong mesh inside the concrete that grips the post better, making it tougher against wind or earthquakes. It's all about spreading out the stress so no single part gets overwhelmed, kind of like a team effort in holding the fort.Is there a need for two bolts?

Ya I don't think so. It's a 24" cube of concrete for a residential deck. Next I'll be hearing about Earth's rotation acting on a soon to be rotted post.Placing rebar in both directions in a concrete-set wood post helps it handle loads coming from any angle, not just straight up and down. It's like creating a strong mesh inside the concrete that grips the post better, making it tougher against wind or earthquakes. It's all about spreading out the stress so no single part gets overwhelmed, kind of like a team effort in holding the fort.

jar546

CBO

Dude, I looked at a pole barn that was not built right and whenever we had sustained winds over 10mph the doors would not open. It was lifting the building slightly on the upwind side and cracking the pavement along side the building.Ya I don't think so. It's a 24" cube of concrete for a residential deck. Next I'll be hearing about Earth's rotation acting on a soon to be rotted post.

And you think that the thru-bolts on the bottom of the posts made a difference? I spent a year or so working for Morton Buildings. We had posts with a rebar stuck through it. We emptied a few bags of dry Sakrete and back-filled. Pulling against dirt is not the same as pulling against a block of concrete.Dude, I looked at a pole barn that was not built right and whenever we had sustained winds over 10mph the doors would not open. It was lifting the building slightly on the upwind side and cracking the pavement along side the building.

I witnessed a tornado pick up a long pole barn. It undulated as it flew across a corn field. Then the tornado caught it and turned it into shrapnel. I could see the rebar on the bottom of the post as the barn wasn't a month old and the little bit of Sakrete hadn't been moist enough to harden.

A 10 mph wind was it? I just knew Earth's rotation would muddy this up.

Last edited:

tbz

SAWHORSE

Interesting post,

I have always been intrigued by the amount of effort that gets focused on the pinning of the post in the concrete and not the concrete to the earth.

I have always been intrigued by the amount of effort that gets focused on the pinning of the post in the concrete and not the concrete to the earth.

- (8) 3/8-Lags, x 4" tapped into a 6x6 at (2) a side in different locations has always been the rule of thumb we have used in the past when actually setting 6x6's in concrete starting way back in the 70's, has worked well other than the rotting of the post in the concrete.

- My question is would not a couple of 90 angle clips with screws or nails if embedding in the concrete pour work just a well?

- The concrete is inside the form is not?

- If you dug a round hole and back filled, is the backfilled ground really tied into the other earth?

- Whay aren't rebars required to be driven into the earth within the hole through the cardboard sonotube form providing pinning to the actual undisturbed Earth?

- It would seem to question would it not make more sense to pin that also?