BayPointArchitect

Sawhorse

Given:

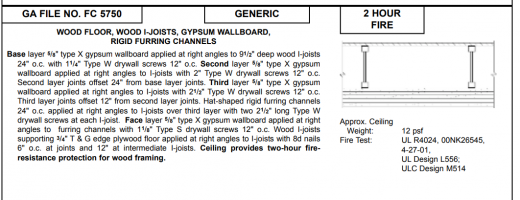

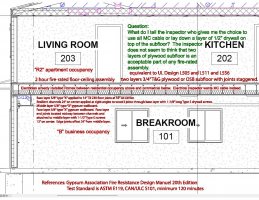

Nonsprinkled, mixed-use occupancy building, wood framing, requiring two-hour fire separation between business office below an apartment unit above.

A floor ceiling assembly that is not in strict accordance with a given UL design number but is equivalent to three UL listed assemblies that have two layers of plywood subfloor.

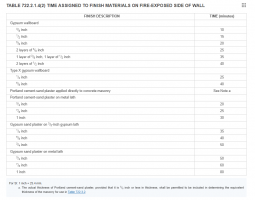

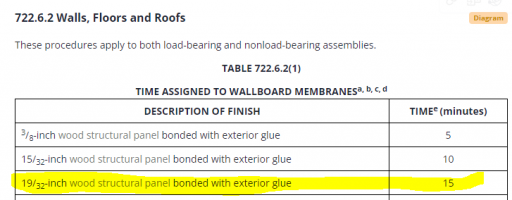

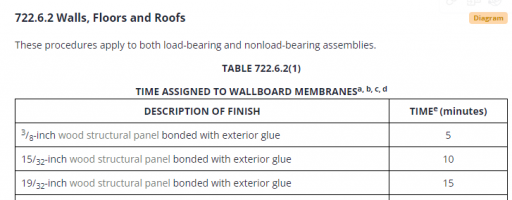

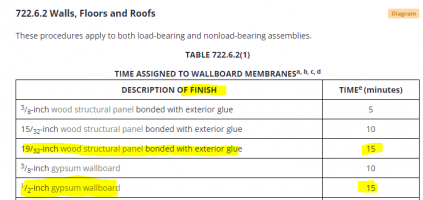

Rather than installing MC cable within the floor-ceiling assembly to supply the residence above and the lights for the business below, the electrician installed Romex to provide power for both the residential and commercial. My thinking (based on the opinion of a different electrical inspector) is that the Romex is acceptable for the residential supply but the power for the office lights needs to be MC cable. The inspector that we are having a problem with makes it clear that he does not like TJI joists because of their poor fire performance. But then he tells the general contractor that all of the existing Romex may remain in place only if the general contractor lays down a layer of 1/2" drywall on top of the subfloor. The inspector explains that two layers of combustible plywood without any additional protection has never been an acceptable combination where a fire-rated floor-ceiling assembly is required. The inspector tells the general contractor to provide a UL number to prove otherwise.

Question:

How should we explain to the electrical inspector that the two layers of plywood on top of the floor framing is okay? How do we say that laying down a layer of 1/2" drywall onto the subfloor is a little weird?

As always, thank you in advance for your advice.

ICC Certified Pan Reviewer

NFPA Certified Fire Plan Examiner

Nonsprinkled, mixed-use occupancy building, wood framing, requiring two-hour fire separation between business office below an apartment unit above.

A floor ceiling assembly that is not in strict accordance with a given UL design number but is equivalent to three UL listed assemblies that have two layers of plywood subfloor.

Rather than installing MC cable within the floor-ceiling assembly to supply the residence above and the lights for the business below, the electrician installed Romex to provide power for both the residential and commercial. My thinking (based on the opinion of a different electrical inspector) is that the Romex is acceptable for the residential supply but the power for the office lights needs to be MC cable. The inspector that we are having a problem with makes it clear that he does not like TJI joists because of their poor fire performance. But then he tells the general contractor that all of the existing Romex may remain in place only if the general contractor lays down a layer of 1/2" drywall on top of the subfloor. The inspector explains that two layers of combustible plywood without any additional protection has never been an acceptable combination where a fire-rated floor-ceiling assembly is required. The inspector tells the general contractor to provide a UL number to prove otherwise.

Question:

How should we explain to the electrical inspector that the two layers of plywood on top of the floor framing is okay? How do we say that laying down a layer of 1/2" drywall onto the subfloor is a little weird?

As always, thank you in advance for your advice.

ICC Certified Pan Reviewer

NFPA Certified Fire Plan Examiner

Last edited: