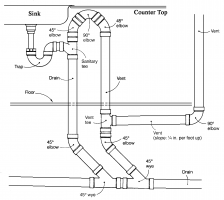

SFR in California, full kitchen remodel. The kitchen sink used to have a wall behind it that contained the vent line. New plan call for the sink to be on a peninsula, same location, so the drain doesn’t change but the vent goes away. Plumber proposes to install an AAV under the counter.

2019 CPC 909.1 calls for the vent line to loop up as high as possible, not less than drainboard height. That implies that a backsplash is needed to get the pipes high enough. Or would you allow the pipe to be below the counter?

2019 CPC 909.1 calls for the vent line to loop up as high as possible, not less than drainboard height. That implies that a backsplash is needed to get the pipes high enough. Or would you allow the pipe to be below the counter?