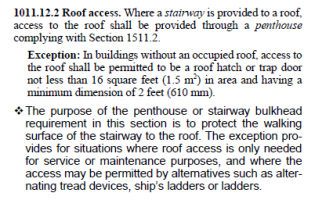

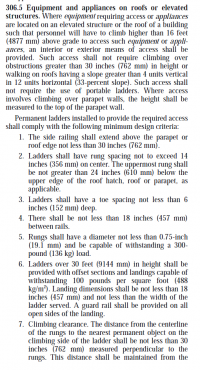

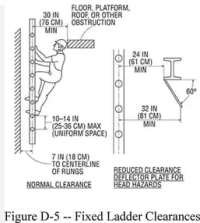

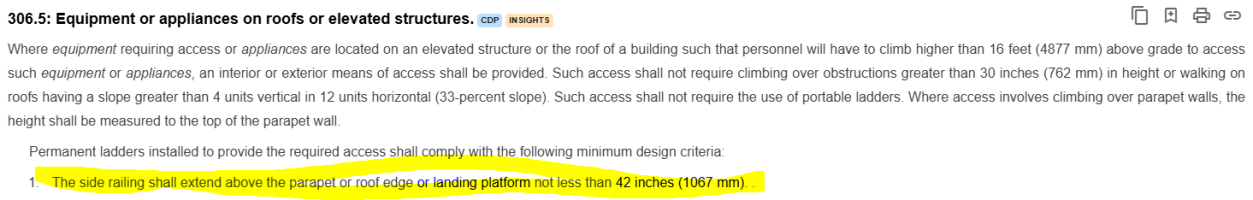

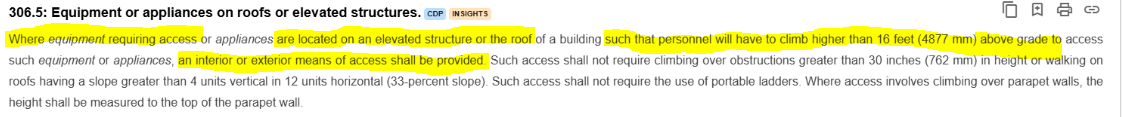

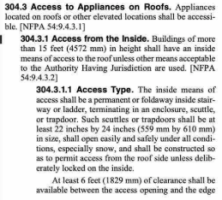

The flat roof I am designing for a 1 story commercial building is 15' above grade. In some places, the roof edge is visible and has a gutter there, and in other locations, there is a parapet that goes up to 16'. For some reason, I thought there was a IBC or OSHA section that allows for roof access to come from a movable ladder (not permanent) and not from a roof hatch. However, now I cannot find those sections anywhere. Does that sound right?

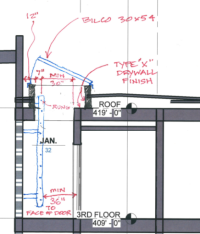

The building is a 10,000 sf footprint, with all of the mechanical equipment hidden behind a screenwall @ the middle portion of the footprint. Would it be a smarter design to provide for a roof hatch within that mechanical yard location, vs a more passive strategy of just saying the owner or workers can access the roof from numerous locations around the building with a movable ladder?

The building is a 10,000 sf footprint, with all of the mechanical equipment hidden behind a screenwall @ the middle portion of the footprint. Would it be a smarter design to provide for a roof hatch within that mechanical yard location, vs a more passive strategy of just saying the owner or workers can access the roof from numerous locations around the building with a movable ladder?