Mr. Inspector

SAWHORSE

2018 IRC requires a #8 copper wire around a spa that is not listed as self-contained in the unpaved or paved perimeter surface 18" to 24" from the inside wall of the spa.

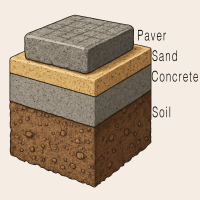

1. If a slab with no steel in it on stone on top of the ground under a spa that is not listed as self-contained goes 20" past the inside walls of the spa and the rest of the perimeter surface is just dirt or grass should the #8 Copper wire be in the dirt or the slab?

2. What if the same spa is on the same slab but the slab only goes out 12" past the inside wall of the spa?

I'm asking because I don't think there would be any continuity between the dirt and the slab and maybe the wire should be in both the ground and the slab.

1. If a slab with no steel in it on stone on top of the ground under a spa that is not listed as self-contained goes 20" past the inside walls of the spa and the rest of the perimeter surface is just dirt or grass should the #8 Copper wire be in the dirt or the slab?

2. What if the same spa is on the same slab but the slab only goes out 12" past the inside wall of the spa?

I'm asking because I don't think there would be any continuity between the dirt and the slab and maybe the wire should be in both the ground and the slab.