jar546

CBO

Cast- In-Place Pipe (CIPP) lining has revolutionized pipe repair since its invention in 1971 by Eric Wood in London, England. This "trenchless" method offers an efficient way to rehabilitate existing pipelines without extensive excavation. The initial process involved inserting a felt tube impregnated with polyester resin into a leaking pipe, then inflating it to allow the resin to cure and form a new, seamless "pipe" within the old one. Remarkably, a pipe rehabilitated with this initial CIPP process in 1971 is still in use as of January 2025.

However, like any evolving technology, CIPP has been subject to a developing framework of standards, codes, and regulatory requirements to ensure its proper and safe application.

Evolution of CIPP Standards: ASTM and Manufacturer Specifications

The establishment of industry standards has been crucial for CIPP technology.

ASTM F1216 (1989): The American Society for Testing and Materials (ASTM) approved ASTM F1216 as the standard for "Standard Practice Rehabilitation of Existing Pipelines and Conduits by the Inversion and Curing of a Resin-Impregnated Tube". This standard mandated "continuous" material installation, producing "dimples" at branch connections, and requiring "remote-controlled cutting tool" reinstatement of these connections.

ASTM F1743 (1996): ASTM further approved F1743 as the "Standard Practice Rehabilitation of Existing Pipelines and Conduits by Pulled-in-Place Installation of Cured-in-Place Thermosetting Resin Pipe". Similar to F1216, this standard also required "continuous" material installation and remote-controlled cutting tool reinstatement for branch connections.

Manufacturers also play a vital role in providing installation guidelines. Perma-Liner Industries, a prominent player, publicly distributed "SPECIFICATIONS FOR INSTALLING CURED-IN-PLACE (CIPP) DRAIN, WASTE, AND VENT PIPE LINING". Initially, in 2013, their specifications noted awareness of alternative reinstatement methods like "Start & Stop," "Gapping," and "Spin-Casting," but stated they did not publish guidelines or offer training for these methods if not offered by Perma-Liner, warning that using them could void warranties. By May 2015, Perma-Liner's updated specifications began publicly distributing an "approval" for the "Gapping" reinstatement method, though they still recommended third-party engineer approval for any alternative reinstatement method.

Florida Building Code and CIPP: A Focus on Regulation

Florida has been at the forefront of establishing clear regulatory requirements for CIPP installations.

DS 2015-106 (November 2015): The Florida Building Commission issued Declaratory Statement 2015-106, a pivotal decision. This statement confirmed that permits are mandatory for the installation of CIPP in residential and existing building drainage systems, as required by Section 105 of the Florida Building Code (5th Edition, 2014). It explicitly affirmed that such work falls under regulated plumbing work, subject to permitting and inspection requirements. Furthermore, it mandated that installations must comply with the manufacturer's published instructions and relevant code sections. This ruling was confirmed by the unanimous vote of the Code Administration TAC and Plumbing TAC, emphasizing that the installation must be in accordance with the manufacturer's instructions and comply with Florida Building Code, Existing Building, Section 609.1 Materials, and Florida Building Code, Plumbing, Section 303.2 Installation and Materials.

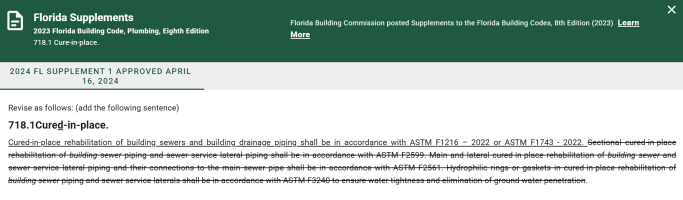

2024 Florida Building Code Supplement (April 2024): The Florida Building Code officially published language requiring CIPP rehabilitation of building sewers and drainage systems to comply with ASTM F1216 and ASTM F174315. These provisions, found in Section 718.1 of the Building Code and Section P3012.1 of the Residential Code, became effective on April 16, 2024, aiming to ensure consistent and compliant code enforcement across the state.

DS 2024-044 (February 2025): A later Declaratory Statement, DS 2024-044, further solidified the requirements. It confirmed that all CIPP rehabilitation must comply with Sections 718.1 and P3012.1 of the 8th Edition Florida Building Code (2023), which mandate adherence to ASTM F1216 and ASTM F174318. Critically, this statement evaluated non-continuous methods like "gapping," "start and stop," or "hybrid" lining. The conclusion was definitive: these segmented approaches have no applicable ASTM standards and therefore do not meet Florida Building Code requirements. Only fully conforming installations performed in accordance with approved ASTM standards are recognized as code-compliant. This decision strongly reinforces the importance of continuous, standards-based CIPP applications for structural drainage rehabilitation22. The urgency of this clarification was underscored by real-world issues, such as a Structural Integrity Reserve Study (SIRS) in May 2024 at Highland Towers, which revealed significant deficiencies related to CIPP "Gapped" material installation.

Proposed Code Modification (June 2025): Looking ahead, the Florida Building Commission is scheduled to review a proposed code modification on June 23, 2025. This modification aims to further clarify and reinforce the Florida Building Code regarding CIPP, explicitly requiring that all CIPP installations comply with ASTM F1216 or ASTM F1743. Both of these standards mandate a continuous liner installation with no gaps at branch or service connections, promoting consistent enforcement and aligning Florida's plumbing code with nationally recognized industry standards.

In summary, the journey of CIPP from an innovative repair method to a fully regulated practice highlights the critical interplay between technological advancement, industry standards (like ASTM), manufacturer guidelines, and evolving building codes. Florida, through its Declaratory Statements and code updates, has progressively tightened regulations, particularly emphasizing the necessity of continuous lining and the rejection of non-standard methods like "gapping" to ensure public safety and code compliance.

video on CIPP problem

However, like any evolving technology, CIPP has been subject to a developing framework of standards, codes, and regulatory requirements to ensure its proper and safe application.

Evolution of CIPP Standards: ASTM and Manufacturer Specifications

The establishment of industry standards has been crucial for CIPP technology.

ASTM F1216 (1989): The American Society for Testing and Materials (ASTM) approved ASTM F1216 as the standard for "Standard Practice Rehabilitation of Existing Pipelines and Conduits by the Inversion and Curing of a Resin-Impregnated Tube". This standard mandated "continuous" material installation, producing "dimples" at branch connections, and requiring "remote-controlled cutting tool" reinstatement of these connections.

ASTM F1743 (1996): ASTM further approved F1743 as the "Standard Practice Rehabilitation of Existing Pipelines and Conduits by Pulled-in-Place Installation of Cured-in-Place Thermosetting Resin Pipe". Similar to F1216, this standard also required "continuous" material installation and remote-controlled cutting tool reinstatement for branch connections.

Manufacturers also play a vital role in providing installation guidelines. Perma-Liner Industries, a prominent player, publicly distributed "SPECIFICATIONS FOR INSTALLING CURED-IN-PLACE (CIPP) DRAIN, WASTE, AND VENT PIPE LINING". Initially, in 2013, their specifications noted awareness of alternative reinstatement methods like "Start & Stop," "Gapping," and "Spin-Casting," but stated they did not publish guidelines or offer training for these methods if not offered by Perma-Liner, warning that using them could void warranties. By May 2015, Perma-Liner's updated specifications began publicly distributing an "approval" for the "Gapping" reinstatement method, though they still recommended third-party engineer approval for any alternative reinstatement method.

Florida Building Code and CIPP: A Focus on Regulation

Florida has been at the forefront of establishing clear regulatory requirements for CIPP installations.

DS 2015-106 (November 2015): The Florida Building Commission issued Declaratory Statement 2015-106, a pivotal decision. This statement confirmed that permits are mandatory for the installation of CIPP in residential and existing building drainage systems, as required by Section 105 of the Florida Building Code (5th Edition, 2014). It explicitly affirmed that such work falls under regulated plumbing work, subject to permitting and inspection requirements. Furthermore, it mandated that installations must comply with the manufacturer's published instructions and relevant code sections. This ruling was confirmed by the unanimous vote of the Code Administration TAC and Plumbing TAC, emphasizing that the installation must be in accordance with the manufacturer's instructions and comply with Florida Building Code, Existing Building, Section 609.1 Materials, and Florida Building Code, Plumbing, Section 303.2 Installation and Materials.

2024 Florida Building Code Supplement (April 2024): The Florida Building Code officially published language requiring CIPP rehabilitation of building sewers and drainage systems to comply with ASTM F1216 and ASTM F174315. These provisions, found in Section 718.1 of the Building Code and Section P3012.1 of the Residential Code, became effective on April 16, 2024, aiming to ensure consistent and compliant code enforcement across the state.

DS 2024-044 (February 2025): A later Declaratory Statement, DS 2024-044, further solidified the requirements. It confirmed that all CIPP rehabilitation must comply with Sections 718.1 and P3012.1 of the 8th Edition Florida Building Code (2023), which mandate adherence to ASTM F1216 and ASTM F174318. Critically, this statement evaluated non-continuous methods like "gapping," "start and stop," or "hybrid" lining. The conclusion was definitive: these segmented approaches have no applicable ASTM standards and therefore do not meet Florida Building Code requirements. Only fully conforming installations performed in accordance with approved ASTM standards are recognized as code-compliant. This decision strongly reinforces the importance of continuous, standards-based CIPP applications for structural drainage rehabilitation22. The urgency of this clarification was underscored by real-world issues, such as a Structural Integrity Reserve Study (SIRS) in May 2024 at Highland Towers, which revealed significant deficiencies related to CIPP "Gapped" material installation.

Proposed Code Modification (June 2025): Looking ahead, the Florida Building Commission is scheduled to review a proposed code modification on June 23, 2025. This modification aims to further clarify and reinforce the Florida Building Code regarding CIPP, explicitly requiring that all CIPP installations comply with ASTM F1216 or ASTM F1743. Both of these standards mandate a continuous liner installation with no gaps at branch or service connections, promoting consistent enforcement and aligning Florida's plumbing code with nationally recognized industry standards.

In summary, the journey of CIPP from an innovative repair method to a fully regulated practice highlights the critical interplay between technological advancement, industry standards (like ASTM), manufacturer guidelines, and evolving building codes. Florida, through its Declaratory Statements and code updates, has progressively tightened regulations, particularly emphasizing the necessity of continuous lining and the rejection of non-standard methods like "gapping" to ensure public safety and code compliance.

video on CIPP problem