-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1 hour fire assembly in a party wall

- Thread starter AEE 11

- Start date

Yankee Chronicler

SAWHORSE

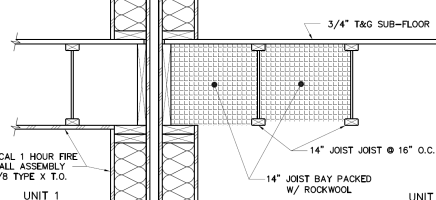

The assembly you show (the overall system) is not a firewall. It is two fire-resistance rated wall assemblies facing each other with what appears to be a 1-inch gap between them. Whatever rating the walls provide is broken at the floor cavity, which is what I assume you are trying to compensate for by packing the joist cavities with mineral wool.

Your note calling for the walls to be pre-assembled doesn't account for how it's going to be possible to install sheetrock and tape the joints through the portion where the rim joists occur. Even if that can be resolved, to use packed mineral wool in the joist cavities as a way of maintaining the fire-resistance rating of the walls you should provide the code official with a U.L. or other test and listing to show that the proposed system will perform as required. I have never seen any U.L., F.M., or other listing for such a system. That doesn't mean it hasn't been tested and listed -- it just means I haven't seen it. You need to perform some research.

What's the application? Does the code require a "firewall" at this location? If so -- you don't have one.

Your note calling for the walls to be pre-assembled doesn't account for how it's going to be possible to install sheetrock and tape the joints through the portion where the rim joists occur. Even if that can be resolved, to use packed mineral wool in the joist cavities as a way of maintaining the fire-resistance rating of the walls you should provide the code official with a U.L. or other test and listing to show that the proposed system will perform as required. I have never seen any U.L., F.M., or other listing for such a system. That doesn't mean it hasn't been tested and listed -- it just means I haven't seen it. You need to perform some research.

What's the application? Does the code require a "firewall" at this location? If so -- you don't have one.

Last edited:

redeyedfly

REGISTERED

It's definitely not a fire wall but it may be a compliant separation of units depending on what type of building this is and which code it is under.

Also, why would you pack the floor with rockwool? That sounds really expensive and unnecessary.

Also, why would you pack the floor with rockwool? That sounds really expensive and unnecessary.

No, it’s not.It's basically irreverent.

Yankee Chronicler

SAWHORSE

It's basically irreverent. The basic argument is if the packed-out rock wool is a substitute for a 5/8" type X drywall ceiling in a crawl space housing a driveway heat boiler.

This is a different question that what you asked in the opening post:

is the attached a valid 1 hour assembly for unit 2?

The first post asks about the wall. The second is asking if the mineral wool packing [shown only in the first two joist bays) is an acceptable substitute for a Type X gypsum board ceiling on the underside of the floor joists.

My answer to the second questions is "No."

The detail shows wood I-Joists. In wood I-joists, typically the top 2x member is in compression and the bottom 2x member is in tension. The vertical panel of oriented strand board just serves to keep the top chord on top and the bottom chord on the bottom. The work is being done by the 2x's, and the gypsum wallboard ceiling is there to protect the I-joists, because they are made up of comparatively small members that will be weakened significantly by even a short exposure to fire. Packing the cavities as shown in your detail provides zero protection for the bottom 2x member, which is the member that does most of the work in supporting the floor.

Whether it is a firewall assembly or not, . . .

The building is a duplex. The area of concern is a crawl space adjacent to a garage. Separated by a party wall(s). It has passed all inspections except for:

"Correction Comments: Building #1

Corrective Action: Please provide Colorado Engineer Stamped structural drawings and Architect stamped drawings from both the Architect of record and the engineer of record detailing the changes being made. There needs to be details for the dwelling separation and the listed assembly being used to obtain the code compliant fire ratings and separations." (Dated: 05/05/2023)

The concern isn’t whether the floor joist is protected, but will the mineral wool stop the spread of fire to the second half of the duplex. The same floor joists in the floor system not adjacent to this wall (in the middle of the crawl space or at the other end of the crawl space) will not have any protection at all. The floor system is not the problem.

For a fire to get to the second half of the duplex, it would have to pass through or around the mineral wool and burn through a 1-1/2” rim board and a 5/8 type X sheet of drywall.

I think that we are all in agreement that there are no test result of any sort. The system is impossible to test using ASTM C665.

Also, the excuse for not dry walling the crawl space was that “there were too many pipe hanging down”. (Plus me thinks that the dry waller did/couldn’t get a whole sheet of drywall down the crawl space access.)

PS: I respect and appreciate all of your comments.

The building is a duplex. The area of concern is a crawl space adjacent to a garage. Separated by a party wall(s). It has passed all inspections except for:

"Correction Comments: Building #1

Corrective Action: Please provide Colorado Engineer Stamped structural drawings and Architect stamped drawings from both the Architect of record and the engineer of record detailing the changes being made. There needs to be details for the dwelling separation and the listed assembly being used to obtain the code compliant fire ratings and separations." (Dated: 05/05/2023)

The concern isn’t whether the floor joist is protected, but will the mineral wool stop the spread of fire to the second half of the duplex. The same floor joists in the floor system not adjacent to this wall (in the middle of the crawl space or at the other end of the crawl space) will not have any protection at all. The floor system is not the problem.

For a fire to get to the second half of the duplex, it would have to pass through or around the mineral wool and burn through a 1-1/2” rim board and a 5/8 type X sheet of drywall.

I think that we are all in agreement that there are no test result of any sort. The system is impossible to test using ASTM C665.

Also, the excuse for not dry walling the crawl space was that “there were too many pipe hanging down”. (Plus me thinks that the dry waller did/couldn’t get a whole sheet of drywall down the crawl space access.)

PS: I respect and appreciate all of your comments.

I know a guy who will stamp anything for $500... Just sayin....Corrective Action: Please provide Colorado Engineer Stamped structural drawings and Architect stamped drawings from both the Architect of record and the engineer of record detailing the changes being made. There needs to be details for the dwelling separation and the listed assembly being used to obtain the code compliant fire ratings and separations." (Dated: 05/05/2023)

I guess @ICE and I need to step up our game. I didn't come here for respect and appreciation.PS: I respect and appreciate all of your comments.

I didn't come here for respect and appreciation.

TheCommish

SAWHORSE

Does the crawl space size qualify for unprotected I joists from below for the floor system?

Last edited:

Yankee Chronicler

SAWHORSE

Why not just use a USG Area Separation Wall assembly? It's made for exactly this application.

www.usg.com

www.usg.com

Area Separation Wall System

USG's Area Separation Wall System are fire-resistant systems create enhanced protection between townhouse units with shared walls.

redeyedfly

REGISTERED

where??Why not just use a USG Area Separation Wall assembly? It's made for exactly this application.

Area Separation Wall System

USG's Area Separation Wall System are fire-resistant systems create enhanced protection between townhouse units with shared walls.www.usg.com