Yikes

SAWHORSE

A CASp recently reminded be that both ADA and CBC 11B 104.1.1state: "All dimensions are subject to conventional industry tolerances EXCEPT where the requirement is STATED as a RANGE with specific MINIMUM AND MAXIMUM end points. "

So tolerances ARE allowed when there is no stated range with specific minimum AND maximum end points. Note the importance of the word "stated".

For example, 804.2.2 states that U-shaped kitchens need a minimum of 60 inches between opposing cabinets, countertops, appliances or walls. If the plans state minimum 60" but it gets built at something less than 60", that may still be acceptable under ADA and 11B, assuming the difference is within "conventional industry tolerances".

Neither ADA nor 11B attempt to definitively answer the question: whose tolerances represent "conventional industry tolerances"? Is it a construction trade association? Is it a widely recognized book published by an individual author, such as David Kent Ballast's "Handbook Of Construction Tolerances"?

It gets even more complicated in this kitchen example. Say the space between a refrigerator and the tile countertop on a cabinet on the opposite wall is 59.5". What tolerance do you reference? Did the rough framer build the wall within industry standard framing tolerances for framing? Did the tile installer follow Tile Council of North America tolerances? The refrigerator manufacturer might say they need min. 1" clearance to the back coils, but did the refrigerator installer put the fridge too far away from the wall? What about the device used to measure the finished clearance - - what is its tolerance? And are all the tolerances cumulative amongst all trades' own tolerances?

The CASp I talked to believes that in that example it is ultimately up to the design professional of record to determine what is considered acceptable tolerances. Of course, in the example above, any installed dimension that is less than the 60" min. is begging for litigation, and even if the DPOR ultimately prevails in court, was it worth the hassle?

Thant's why the USDOJ has issued an advisory stating that:

(1) DPORs should avoid stating a construction tolerance on plan that is noncompliant with the stated minimum or maximum.

(2) DPOR should consider baking in the tolerance on the stated dimension:

Example, if the DPOR has somehow determined that 1/4" construction tolerance at the kitchen width is a "conventional industry tolerance":

Lastly, in 104.1.1 notice the importance of the word "stated" in describing both the minimum and maximum end points. Implied zero or infinity does not count as a stated range. If a regulation says "maximum 5 lbs. force" but does not state it as "0 - 5 lbs. force", then it is not a "stated range" and therefore conventional industry tolerances are allowed to apply to the max. 5 lbs. force.

*******************************************************

Excerpt from DOJ advisory:

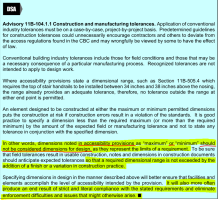

Conventional industry tolerances recognized by this provision include those for field conditions and those that may be a necessary consequence of a particular manufacturing process. Recognized tolerances are not intended to apply to design work.

It is good practice when specifying dimensions to avoid specifying a tolerance where dimensions are absolute. For example, if this document requires “1 inches,” avoid specifying “1 inches plus or minus X inches.”

Where the requirement states a specified range, such as in Section 609.4 where grab bars must be installed between 33 inches and 36 inches above the floor, the range provides an adequate tolerance and therefore no tolerance outside of the range at either end point is permitted.

Where a requirement is a minimum or a maximum dimension that does not have two specific minimum and maximum end points, tolerances may apply. Where an element is to be installed at the minimum or maximum permitted dimension, such as “15 inches minimum” or “5 pounds maximum”, it would not be good practice to specify “5 pounds (plus X pounds) or 15 inches (minus X inches).” Rather, it would be good practice to specify a dimension less than the required maximum (or more than the required minimum) by the amount of the expected field or manufacturing tolerance and not to state any tolerance in conjunction with the specified dimension.

Specifying dimensions in design in the manner described above will better ensure that facilities and elements accomplish the level of accessibility intended by these requirements. It will also more often produce an end result of strict and literal compliance with the stated requirements and eliminate enforcement difficulties and issues that might otherwise arise. Information on specific tolerances may be available from industry or trade organizations, code groups and building officials, and published references.

So tolerances ARE allowed when there is no stated range with specific minimum AND maximum end points. Note the importance of the word "stated".

For example, 804.2.2 states that U-shaped kitchens need a minimum of 60 inches between opposing cabinets, countertops, appliances or walls. If the plans state minimum 60" but it gets built at something less than 60", that may still be acceptable under ADA and 11B, assuming the difference is within "conventional industry tolerances".

Neither ADA nor 11B attempt to definitively answer the question: whose tolerances represent "conventional industry tolerances"? Is it a construction trade association? Is it a widely recognized book published by an individual author, such as David Kent Ballast's "Handbook Of Construction Tolerances"?

It gets even more complicated in this kitchen example. Say the space between a refrigerator and the tile countertop on a cabinet on the opposite wall is 59.5". What tolerance do you reference? Did the rough framer build the wall within industry standard framing tolerances for framing? Did the tile installer follow Tile Council of North America tolerances? The refrigerator manufacturer might say they need min. 1" clearance to the back coils, but did the refrigerator installer put the fridge too far away from the wall? What about the device used to measure the finished clearance - - what is its tolerance? And are all the tolerances cumulative amongst all trades' own tolerances?

The CASp I talked to believes that in that example it is ultimately up to the design professional of record to determine what is considered acceptable tolerances. Of course, in the example above, any installed dimension that is less than the 60" min. is begging for litigation, and even if the DPOR ultimately prevails in court, was it worth the hassle?

Thant's why the USDOJ has issued an advisory stating that:

(1) DPORs should avoid stating a construction tolerance on plan that is noncompliant with the stated minimum or maximum.

(2) DPOR should consider baking in the tolerance on the stated dimension:

Example, if the DPOR has somehow determined that 1/4" construction tolerance at the kitchen width is a "conventional industry tolerance":

- ACCEPTABLE PRACTICE is to state on the plans: minimum 60" clear

- NOT GOOD PRACTICE is to state on the plans: minimum 60" clear +/- 1/4" construction tolerance

- GOOD PRACTICE is to state: minimum 60 1/4" clear.

Lastly, in 104.1.1 notice the importance of the word "stated" in describing both the minimum and maximum end points. Implied zero or infinity does not count as a stated range. If a regulation says "maximum 5 lbs. force" but does not state it as "0 - 5 lbs. force", then it is not a "stated range" and therefore conventional industry tolerances are allowed to apply to the max. 5 lbs. force.

*******************************************************

Excerpt from DOJ advisory:

Conventional industry tolerances recognized by this provision include those for field conditions and those that may be a necessary consequence of a particular manufacturing process. Recognized tolerances are not intended to apply to design work.

It is good practice when specifying dimensions to avoid specifying a tolerance where dimensions are absolute. For example, if this document requires “1 inches,” avoid specifying “1 inches plus or minus X inches.”

Where the requirement states a specified range, such as in Section 609.4 where grab bars must be installed between 33 inches and 36 inches above the floor, the range provides an adequate tolerance and therefore no tolerance outside of the range at either end point is permitted.

Where a requirement is a minimum or a maximum dimension that does not have two specific minimum and maximum end points, tolerances may apply. Where an element is to be installed at the minimum or maximum permitted dimension, such as “15 inches minimum” or “5 pounds maximum”, it would not be good practice to specify “5 pounds (plus X pounds) or 15 inches (minus X inches).” Rather, it would be good practice to specify a dimension less than the required maximum (or more than the required minimum) by the amount of the expected field or manufacturing tolerance and not to state any tolerance in conjunction with the specified dimension.

Specifying dimensions in design in the manner described above will better ensure that facilities and elements accomplish the level of accessibility intended by these requirements. It will also more often produce an end result of strict and literal compliance with the stated requirements and eliminate enforcement difficulties and issues that might otherwise arise. Information on specific tolerances may be available from industry or trade organizations, code groups and building officials, and published references.