jwelectric

Silver Member

I was addressing 250.53(D)(1).If the electrician choses he can install a jumper from the underground metal water pipe to the interior metal water pipe or the electrician can install a bonding jumper from the interior metal water pipe to one of the other three places outlined in 250.104(A)(1)RJJ said:JW: 250.104 (1) Does not say "if we so desire" it says Shall!

1- the service equipment enclosure,

2- the grounded conductor at the service,

3- the grounding electrode conductor where of sufficient size

The Title of Section 250.104 “Bonding of Piping Systems and Exposed Structural Steel” and includes the rules for bonding these two systems. I cannot find a requirement in this section to make a metal pipe system electrically continuous by installing a bonding jumper or jumpers between insolated parts.

If we look at 250.52(A)(1) we see the mention of electrically continuity but not in 250.104. Wonder why they forgot to include this in the bonding requirements?

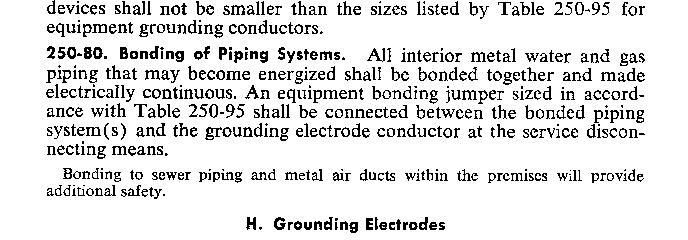

It used to be a requirement see the insert from 1975

If it was so important why was it removed from the NEC? Answer- Because the electrician has no control over the plumber nor does the electrical code enforcement official.

Article 602 of the ICC Plumbing code is the requirement for water supply to a building. It does not require a water heater to be installed.

Here is what the plumbing code says about fixtures in a building:

602.2 Potable water required.

Only potable water shall be supplied to plumbing fixtures that provide water for drinking, bathing or culinary purposes, or for the processing of food, medical or pharmaceutical products. Unless otherwise provided in this code, potable water shall be supplied to all plumbing fixtures.

It does not break it down into two different types of water but it is only one system and needs to be bonded in one place.

The Code Making Panel said in their statement;

If it is possible to use a cheap millimeter and not have continuity from any point to any other point on a piping system then it is not a complete metallic system.Panel Statement: The conditions indicated in the substantiation are already covered by 250.104(B) where there is not a complete metallic water piping system.