iOne

REGISTERED

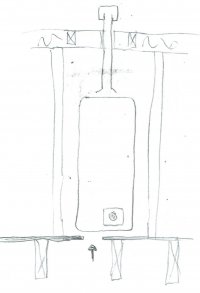

I working on a retroactive permit situation / code enforcement on a water heater closet that looks like the attached image.

The closet is interior in a 200 square foot studio unit, the water heater is a 30k BTU flue vented gas tank water heater.

The closet has a latching door with no vents in the door.

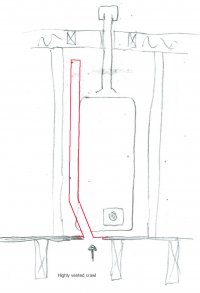

I read the code incorrectly and specified a 10 square inch vent through the floor to the crawl space below.

Under 304.6.2 One-permanent-opening method (California Mechanical Code 701.6.2) looks like I screwed up. The opening has to be in the ceiling.

The closet is interior in a 200 square foot studio unit, the water heater is a 30k BTU flue vented gas tank water heater.

The closet has a latching door with no vents in the door.

I read the code incorrectly and specified a 10 square inch vent through the floor to the crawl space below.

Under 304.6.2 One-permanent-opening method (California Mechanical Code 701.6.2) looks like I screwed up. The opening has to be in the ceiling.

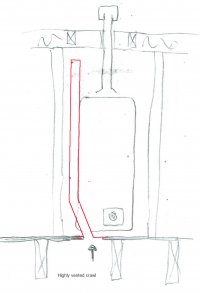

- My question is why?

- Would the ceiling mounted one opening vent perform better?

- Can I run a 3x4" or 2" round duct from the floor to within 12" of the ceiling and call it good?