Meadowbend99

REGISTERED

Hi,

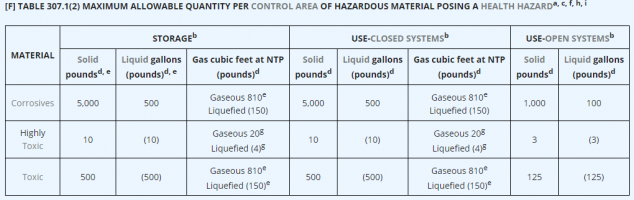

I'm doing my first H occupancy and am looking for some direction on the best way to determine which H it would be classified as.

It's a small, 7,500 SF, metal finishing shop. It consists of tanks with solutions, rinses, dyes to dip/finish metal.

Chemicals that will be used and stored on site include: AL CLENETM 75R (section 2), CLEANER 3390G (hazard level 2), CORAKTM 777L (hazard level 2), ISOPREP 35 (section 2).

Since chemicals are considered hazard level 2, does that make this an H-2?

The plan is to build a storage building detached from the building for bulk chemical storage.

Thanks!

I'm doing my first H occupancy and am looking for some direction on the best way to determine which H it would be classified as.

It's a small, 7,500 SF, metal finishing shop. It consists of tanks with solutions, rinses, dyes to dip/finish metal.

Chemicals that will be used and stored on site include: AL CLENETM 75R (section 2), CLEANER 3390G (hazard level 2), CORAKTM 777L (hazard level 2), ISOPREP 35 (section 2).

Since chemicals are considered hazard level 2, does that make this an H-2?

The plan is to build a storage building detached from the building for bulk chemical storage.

Thanks!