-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

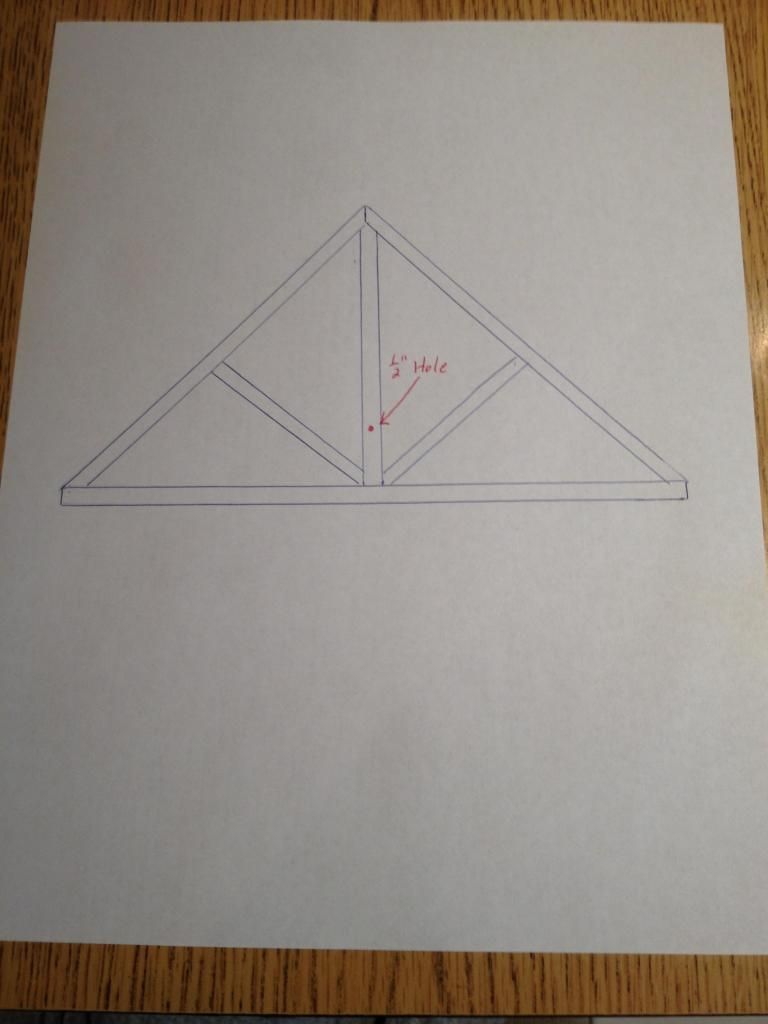

Drilling roof truss

- Thread starter chris kennedy

- Start date

chris kennedy

ADMIN

Looks like a no go as per R802.7.2.

Tell me I'm missing something.

Tell me I'm missing something.

I would expect a RDP to readily sign off on your modification. Check with the truss manufacturer.R802.7.2 ...except where permitted by the manufacturer’s recommendations or where the effects of such alterations are specifically considered in the design of the member by a registered design professional.

Francis Vineyard

REGISTERED

Chris, correct the alternative is to provide an engineered design. Contact the manufacturer's representative.

Could also search their site for approved repairs such as "Mitek repair details".

There is also a site that sells inexpensive and quick pre-engineered metal plates for repairs permitted by the AHJ.

Could also search their site for approved repairs such as "Mitek repair details".

There is also a site that sells inexpensive and quick pre-engineered metal plates for repairs permitted by the AHJ.

fatboy

Administrator

I agree that the engineer that stamped the original drawing should approve alternations, realistically, I don't how that I could be concerned with it in the field. Just curious why you must make the hole anyway?

Sifu

SAWHORSE

- Joined

- Sep 3, 2011

- Messages

- 3,572

Agree that technically the rdp must sign off, also agree that such a small alteration probably won't be a big deal. Question is the weight of the object and will it exceed the design load of the truss. Probably not but if it needs a steel cable to carry it that might be worth a quick double check. Probably a question the rdp will want answered too.

I wouldn't be concerned about it. Just stay a foot away from any gussets. Why so big for a cable that's less than I/4"? If the cable will be sliding back and forth, you might consider a sleeve.

Last edited by a moderator:

chris kennedy

ADMIN

Dead center of where I need to place 2 pulleys for the lift. I spent 4hrs there Tues trying to find an alternative for this craptacular design.fatboy said:Just curious why you must make the hole anyway?

Cable needs to pass through the hole without contacting the truss, just a hole, no load imposed.Sifu said:Question is the weight of the object and will it exceed the design load of the truss. Probably not but if it needs a steel cable to carry it that might be worth a quick double check.

Need wiggle room as the cable cannot contact the truss.ICE said:Why so big for a cable that's less than I/4"?

fatboy

Administrator

Props to you for asking the question ahead of time, instead asking forgiveness at the the time of inspection.

Msradell

SAWHORSE

Knowing the nature of this project, I'm betting it's not going to be inspected nor a permit obtained for it. Something I normally don't agree with but in this case I certainly don't see a reason for a permit nor inspection.fatboy said:Props to you for asking the question ahead of time, instead asking forgiveness at the the time of inspection.

chris kennedy

ADMIN

New home (McMansion) getting rough MEP's and framing inspections next week.

steveray

SAWHORSE

I have seen it done and approved 100's of times....truss company will give an OK or reinforcement detail...

Wait until the week after.chris kennedy said:New home (McMansion) getting rough MEP's and framing inspections next week.

kyhowey

Silver Member

Drilling a hole would require the OK from the truss manufacturer. If the lift system is for anything other than lights, I would be concerned about overloading the truss as well.

JBI

REGISTERED

Agree with the above. Truss manufacturer or RDP. On a new home the manufacturer will probably be easily identified and their Engineers can sign off.