I just got a call from a construction supply yard asking if "Foam Core" ABS is permitted instead of "regular" ABS. I've never seen it or heard of it, apparently it's an East Coast product. Is it treated the same a ABS from a code enforcement standpoint? Thanks.

-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Foam core ABS

- Thread starter Joe.B

- Start date

According to google, yes that is the same. Problem is code doesn't list either of those as an allowable material for DWV piping. My book lists ABS (schedule 40), Co-Extruded ABS (schedule 40), or Co-Extruded Composite (schedule 40) among the listed "approved" materials. I'm leaning towards allowing it but just looking for anybody with experience using, or approving this product. Thanks.

FYI, Foam Core is typically the same thing as Co-Extruded.

Now, to get to it... here is an example material submittal form from Charlotte Pipe and Foundry.

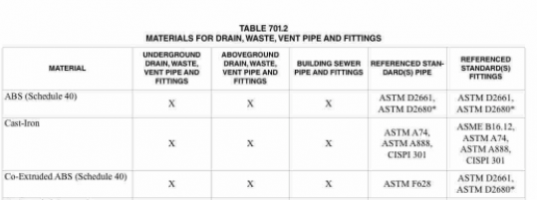

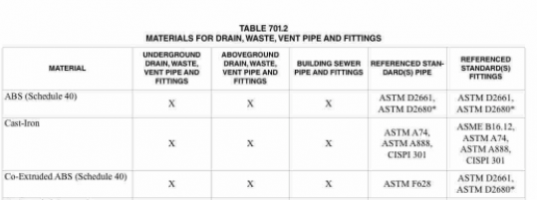

For acceptable materials for DWV/sewer (if you use the UPC), see Table 701.2 (below)

Now, putting the two images above together, we can see that the Charlotte Pipe and Foundry Foam Core ABS is tested to ASTM D2661 (fittings) and F628 (pipe). The same ASTM are referenced for Co-Extruded ABS under Table 701.2.

Therefore, if following the UPC, no issue. Can not definitively say the IPC is the same, but I would not suspect any difference.

Now, to get to it... here is an example material submittal form from Charlotte Pipe and Foundry.

For acceptable materials for DWV/sewer (if you use the UPC), see Table 701.2 (below)

Now, putting the two images above together, we can see that the Charlotte Pipe and Foundry Foam Core ABS is tested to ASTM D2661 (fittings) and F628 (pipe). The same ASTM are referenced for Co-Extruded ABS under Table 701.2.

Therefore, if following the UPC, no issue. Can not definitively say the IPC is the same, but I would not suspect any difference.

As I mentioned in the above post, Foam-Core = Co-ExtrudedCo-Extruded ABS (schedule 40)

Keystone

SAWHORSE

2018 IPC, Coextruded ABS is an approved material

codes.iccsafe.org

codes.iccsafe.org

I’m on the East Coast and haven the seen ABS used except for the far and between DIY job trying to mix ABS and PVC because that’s all Billy Bob’s hardware had and they said I’d be okay to use both.

CHAPTER 7 SANITARY DRAINAGE - 2018 INTERNATIONAL PLUMBING CODE (IPC)

ICC Digital Codes is the largest provider of model codes, custom codes and standards used worldwide to construct safe, sustainable, affordable and resilient structures.

I’m on the East Coast and haven the seen ABS used except for the far and between DIY job trying to mix ABS and PVC because that’s all Billy Bob’s hardware had and they said I’d be okay to use both.

Excellent! Thank you so much!As I mentioned in the above post, Foam-Core = Co-Extruded

steveray

SAWHORSE

All in the ASTM # on the pipe

Mr. Inspector

SAWHORSE

I only saw this type of pipe once. The plumber could not pass a pressure test with air. I don't know why. It kept leaking at the fittings no matter what he did. After a few tries he ended up tearing it out and replacing it with PVC.

That brings up another question. How common is testing plastic piping with air pressure? CA plumbing code (based off of UPC) specifically prohibits it, but occasionally I get someone who adamantly insists "that's how it's done." Does IPC allow this?I only saw this type of pipe once. The plumber could not pass a pressure test with air. I don't know why. It kept leaking at the fittings no matter what he did. After a few tries he ended up tearing it out and replacing it with PVC.

Mr. Inspector

SAWHORSE

90% of testing I see is with air on plastic pipes. When I was a brand new inspector and failed my first pressure test for using air my boss asked me if I wanted to continue working as an inspector. Since then I worked for 4 different inspection companies where all of the inspectors are OK with it. Also it is below freezing for 1/3 of the year.

Keystone

SAWHORSE

Majority of tests my way are air.

north star

MODERATOR

- Joined

- Oct 19, 2009

- Messages

- 4,596

@ ~ @ ~ @

Joe.B, ...what does your legally adopted Codes

say about using air to test with [ i.e. - follow

what has been legally adopted in your AHJ ] ?

@ ~ @ ~ @

Joe.B, ...what does your legally adopted Codes

say about using air to test with [ i.e. - follow

what has been legally adopted in your AHJ ] ?

@ ~ @ ~ @

Mr. Inspector

SAWHORSE

Just what the IRC says. But sometimes you need to do other to keep your job.

Air testing plastic DWV pipe is expressly prohibited by CA plumbing code (2019 CPC 723.1)