jar546

Forum Coordinator

Introduction

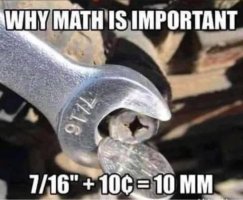

The United States stands as one of the last bastions of the imperial measurement system, a vestige of British colonial history that persists in our daily lives and, critically, in our industries. While many sectors, particularly in manufacturing, have already recognized the merits of the metric system and made the switch, the building industry largely continues to measure in feet and inches. This article aims to build a compelling case for why the United States, and especially its building sector, should transition to the metric system once and for all.The Logical Appeal of Metric

The metric system, designed on a base-10 structure, is universally easier to understand and apply. Conversions are straightforward, involving nothing more complex than shifting a decimal point. In construction, where precision is paramount, the straightforward nature of metric calculations can substantially reduce the margin for error. While the imperial system involves complex fractions and inconsistent unit conversions (12 inches in a foot, 3 feet in a yard, 1,760 yards in a mile), metric is seamless and intuitive.Global Competitiveness

In a world where the metric system is the lingua franca of measurement, adherence to an archaic system hampers the U.S. building industry's competitiveness on the global stage. Many American companies involved in international projects have to convert their plans and components to metric, adding unnecessary complexity and room for error. It’s not just a matter of “translating” units; it’s about rethinking the entire design and construction process to align with global standards.Learning Curve and Resistance

The most common argument against switching is the learning curve. Many fear that generations of architects, builders, and inspectors trained in the imperial system will struggle to adapt. However, this argument overlooks the reality that numerous professions have successfully transitioned. A significant portion of U.S. manufacturing, for example, now operates exclusively in metric, despite the broader nation’s reluctance to switch. These sectors have demonstrated that the initial inconvenience of learning a new system is short-lived and outweighed by long-term benefits.Financial and Logistical Implications

One of the lesser-discussed advantages of a universal metric system in the building industry is the potential cost-saving and logistical streamlining. Existing manufacturing companies that have switched to metric no longer need to maintain dual inventories or deal with conversion errors, leading to increased efficiency and reduced operational costs. The building industry, if it were to switch, could expect similar financial benefits in the long run.Addressing Cultural Resistance

The resistance to the metric system isn't just practical; it's cultural. Many Americans view the imperial system as a part of their national identity. But it's worth asking: Should nostalgia dictate the way we build the future? Metrication is not a surrender of cultural identity but an embrace of global collaboration and technological advancement.Conclusion

The metric system offers a logical, efficient, and globally recognized method of measurement that is already widely used in many U.S. industries, including manufacturing. The building sector, by clinging to the imperial system, not only perpetuates inefficiencies but also limits its competitiveness and adaptability in a world that has largely moved on. It's time for the U.S. building industry to make the metric switch, embracing the short learning curve as a necessary step towards long-term gains in efficiency, safety, and global relevance.The argument for metrication in the U.S. building industry is not just about aligning with global standards but about optimizing for efficiency, precision, and innovation. A shift to the metric system is not just inevitable; it is imperative.