-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

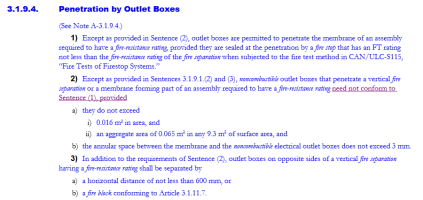

Outlet Boxes

- Thread starter Plumb-bob

- Start date

I do not see how the requirement from #3 that notes being in addition to #2 requirements would somehow affect the exception #1. The way I read this code section outlet boxes with the appropriate putty pads could be placed opposite each other based upon exception #1. But I do not speak Canadian.

steveray

SAWHORSE

I would think the putty packs would meet #1.....No?

The way I read it, the requirements of #s 1 and 2 are met. However, if you wish to place outlet boxes on opposite sides of a vertical fire separation, you need to meet #3, as these requirements are in addition to #s 1 and 2. Am I crazy?

steveray

SAWHORSE

I think it is comply with #1 or ....2 and 3.....The way I read it, the requirements of #s 1 and 2 are met. However, if you wish to place outlet boxes on opposite sides of a vertical fire separation, you need to meet #3, as these requirements are in addition to #s 1 and 2. Am I crazy?

#3 says in addition to #2. Separation or a fireblock is required.

Out of curiosity, how do the American codes speak to this?

In California.............

714.4.2Membrane penetrations.

Membrane penetrations shall comply with Section 714.4.1. Where walls or partitions are required to have a fire-resistance rating, recessed fixtures shall be installed such that the required fire resistance will not be reduced.Exceptions:

- 1.Membrane penetrations of maximum 2-hour fire-resistance-rated walls and partitions by steel electrical boxes that do not exceed 16 square inches (0.0 103 m2) in area, provided that the aggregate area of the openings through the membrane does not exceed 100 square inches (0.0645 m2) in any 100 square feet (9.29 m2) of wall area. The annular space between the wall membrane and the box shall not exceed 1/8 inch (3.2 mm). Such boxes on opposite sides of the wall or partition shall be separated by one of the following:

- 1.1.By a horizontal distance of not less than 24 inches (610 mm) where the wall or partition is constructed with individual noncommunicating stud cavities.

- 1.2.By a horizontal distance of not less than the depth of the wall cavity where the wall cavity is filled with cellulose loose-fill, rockwool or slag mineral wool insulation.

- 1.3.By solid fireblocking in accordance with Section 718.2.1.

- 1.4.By protecting both outlet boxes with listed putty pads.

- 1.5.By other listed materials and methods.

- 2.Membrane penetrations by listed electrical boxes of any material, provided that such boxes have been tested for use in fire-resistance-rated assemblies and are installed in accordance with the instructions included in the listing. The annular space between the wall membrane and the box shall not exceed 1/8 inch (3.2 mm) unless listed otherwise. Such boxes on opposite sides of the wall or partition shall be separated by one of the following:

- 2.1.By the horizontal distance specified in the listing of the electrical boxes.

- 2.2.By solid fireblocking in accordance with Section 718.2.1.

- 2.3.By protecting both boxes with listed putty pads.

- 2.4.By other listed materials and methods.

- 3.Membrane penetrations by electrical boxes of any size or type, that have been listed as part of a wall opening protective material system for use in fire-resistance-rated assemblies and are installed in accordance with the instructions included in the listing.

- 4.Membrane penetrations by boxes other than electrical boxes, provided that such penetrating items and the annular space between the wall membrane and the box, are protected by an approved membrane penetration firestop system installed as tested in accordance with ASTM E814 or UL 1479, with a minimum positive pressure differential of 0.01 inch (2.49 Pa) of water, and shall have an F and T rating of not less than the required fire-resistance rating of the wall penetrated and be installed in accordance with their listing.

- 5.The annular space created by the penetration of an automatic sprinkler, provided that it is covered by a metal escutcheon plate.

- 6.Membrane penetrations of maximum 2-hour fire-resistance-rated walls and partitions by steel electrical boxes that exceed 16 square inches (0.0 103 m2) in area, or steel electrical boxes of any size having an aggregate area through the membrane exceeding 100 square inches (0.0645 m2) in any 100 square feet (9.29 m2) of wall area, provided that such penetrating items are protected by listed putty pads or other listed materials and methods, and installed in accordance with the listing.

I am curious. Is there a stated life span for putty pads? Have you encountered pads that relaxed to the point of openings being created?

Last edited:

Inspector Gadget

REGISTERED

Pads <> fire block in this instance. I'd accept "bulkheading" one of the outlets with F/R drywall, though.

Pads are a fire stop, not a fire block.Pads <> fire block in this instance. I'd accept "bulkheading" one of the outlets with F/R drywall, though.

I put in an interpretation request, I will try to remember to post the answer here when it comes in, which could be months away.

Inspector Gadget

REGISTERED

Pads are a fire stop, not a fire block.

I put in an interpretation request, I will try to remember to post the answer here when it comes in, which could be months away.

Augh. The backward < makes my comment look like "Pads are not equal to a fire stop rather than what I intended, which is Pads > fire block, ie, Pads are better than a fire block.

Insufficient coffee when posting.

10-4 thanks.

FYI to all involved, there is an excellent publication from the National Research Council on fire stops and fire blocks. May even be of interest to our American friends! Very dry and technical, but I found it very informative.

FYI to all involved, there is an excellent publication from the National Research Council on fire stops and fire blocks. May even be of interest to our American friends! Very dry and technical, but I found it very informative.

tmurray

SAWHORSE

I had an issue recently where the designer and contractor punched a bunch of holes in the exit enclosure for boxes. Local B-O identified it on the plan review and multiple inspections. You can't put recessed boxes in an exit enclosure, even firestopped. So, they submitted an alternative solution to firestop them.

Issues with the solution:

The design referenced a fire rated assembly from Part 9 for a Part 3 building

Hilti requires the packs to only be used in ULC listed assemblies.

The fire protection engineer they hired did not address either issue.

The level of performance to be demonstrated is that the assembly functions as good or better than if the penetrations were not there in the first place. The statement of "we firestopped them to the same fire resistance rating, so it should be fine" doesn't fly. No empirical data to support the conclusion was provided.

Issues with the solution:

The design referenced a fire rated assembly from Part 9 for a Part 3 building

Hilti requires the packs to only be used in ULC listed assemblies.

The fire protection engineer they hired did not address either issue.

The level of performance to be demonstrated is that the assembly functions as good or better than if the penetrations were not there in the first place. The statement of "we firestopped them to the same fire resistance rating, so it should be fine" doesn't fly. No empirical data to support the conclusion was provided.

TheCommish

SAWHORSE

I have seen sheetrock boxes build around recessed assemblies, would the gallery accept this method?

tmurray

SAWHORSE

If the rating is derived from the membrane only, that would be acceptable. But, when an assembly approach is used, I don't think there would be justification in the code for it.I have seen sheetrock boxes build around recessed assemblies, would the gallery accept this method?

Yankee Chronicler

SAWHORSE

I have seen sheetrock boxes build around recessed assemblies, would the gallery accept this method?

Only if there's a U.L. or Warnock-Hersey or equivalent detail showing that such has been tested to demonstrate that it performs to the fire-resistance rating required (1-hour or 2-hour).

Yankee Chronicler

SAWHORSE

If the rating is derived from the membrane only, that would be acceptable. But, when an assembly approach is used, I don't think there would be justification in the code for it.

From Chapter 10 of the IBC:

1023.5 Penetrations. Penetrations into or through interior exit

stairways and ramps are prohibited except for the following:

1. Equipment and ductwork necessary for independent

ventilation or pressurization.

2. Fire protection systems.

3. Security systems.

4. Two-way communication systems.

5. Electrical raceway for fire department communication

systems.

6. Electrical raceway serving the interior exit stairway

and ramp and terminating at a steel box not exceeding

16 square inches (0.010 m2).

7. Structural elements supporting the interior exit stairway

or ramp or enclosure, such as beams or joists.

Such penetrations shall be protected in accordance with

Section 714. There shall not be penetrations or communication

openings, whether protected or not, between adjacent interior

exit stairways and ramps.

Exception: Membrane penetrations shall be permitted on

the outside of the interior exit stairway and ramp. Such

penetrations shall be protected in accordance with Section

714.4.2.

As section 1023.5 states in the opening sentence, there are two types of penetrations: through penetrations (from whatever is outside the exit enclosure all the way through the wall and into the exit), and membrane penetrations (through one side of the enclosure wall into the wall cavity). Neither through penetrations nor membrane penetrations are allowed unless they are for equipment that serves the exit -- except that membrane penetrations ARE allowed if protected per IBC 714.4.2.

tmurray

SAWHORSE

Sorry, I thought we were still discussing general allowances, not my foray into exits.From Chapter 10 of the IBC:

As section 1023.5 states in the opening sentence, there are two types of penetrations: through penetrations (from whatever is outside the exit enclosure all the way through the wall and into the exit), and membrane penetrations (through one side of the enclosure wall into the wall cavity). Neither through penetrations nor membrane penetrations are allowed unless they are for equipment that serves the exit -- except that membrane penetrations ARE allowed if protected per IBC 714.4.2.

You'll get limited mileage (kilometerage?) out of IBC references in Canada.

Yankee Chronicler

SAWHORSE

You'll get limited mileage (kilometerage?) out of IBC references in Canada.

Does the CBC have a different distinction between membrane penetrations and through penetrations? Item #1 in the code section you reproduced specifically addresses membrane penetrations, so I suspect the concept is the same on both side of the border.

tmurray

SAWHORSE

Our favorite answer: it depends.Does the CBC have a different distinction between membrane penetrations and through penetrations? Item #1 in the code section you reproduced specifically addresses membrane penetrations, so I suspect the concept is the same on both side of the border.

Assembly vs. membrane approach to rating impacts it.

That clause has more to do with the location of the firestopping material to ensure it does not enter a cavity than dealing with membrane vs. through penetrations.