BakingFool

REGISTERED

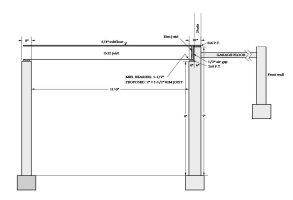

My new home design calls for 11′ wide by 14’long entryway that sits between the living space and garage, at the same floor level as the living space. Floor support is 2×12 joists, and the exterior walls are 2×6 construction. There is a u-shaped stairway in the entryway to the full basement under the living area.

The house was designed with 8′ foundation walls, and had a rise from the garage floor to the subfloor of 17-1/2″: 4″ for vapors + 1-1/2″ sill+ 11-1/4″ joist + 3/4″ sublfoor. For multiple reasons (steps, topography, fill and grading) I would like to lower the living area and entry to have only one step up from the garage.

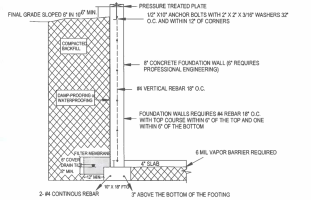

I came up with the idea in the attached diagram. The code I researched calls for a sill plate and bearing on concrete of at least the width of the studs. The minimum bearing length required for 2×12 joists is 1-1/2″. For the foundation wall between the entryway and garage I am proposing to use a 9′ high, 10″ thick wall, with a 4″ wide step at 8′. All other foundation walls will be 8′ even with the step at 8', except garage walls which will be 4′ frost walls even with the top of the 9' wall in the diagram.

I am interested feedback on this proposed solution. Any obvious problems with this plan? Thank you in advance,

Don

The house was designed with 8′ foundation walls, and had a rise from the garage floor to the subfloor of 17-1/2″: 4″ for vapors + 1-1/2″ sill+ 11-1/4″ joist + 3/4″ sublfoor. For multiple reasons (steps, topography, fill and grading) I would like to lower the living area and entry to have only one step up from the garage.

I came up with the idea in the attached diagram. The code I researched calls for a sill plate and bearing on concrete of at least the width of the studs. The minimum bearing length required for 2×12 joists is 1-1/2″. For the foundation wall between the entryway and garage I am proposing to use a 9′ high, 10″ thick wall, with a 4″ wide step at 8′. All other foundation walls will be 8′ even with the step at 8', except garage walls which will be 4′ frost walls even with the top of the 9' wall in the diagram.

I am interested feedback on this proposed solution. Any obvious problems with this plan? Thank you in advance,

Don