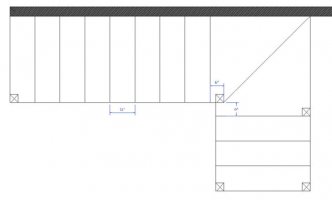

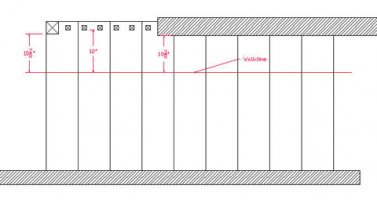

Hopefully I've attached a picture of a winder I'm having difficulty laying out. I think I've thought it into that dark place where a winder is unbuildable. If you can see what's going on with my thought process/ brain fart here and can talk me down, I'd sure appreciate it. The posts are drawn at 3.5" square, when I try to get to 6" I end up with a point in space. Advice on the measurement points for the 12" walkline would be helpful as well.

View attachment 1393

View attachment 1393

/monthly_2010_09/572953dd1be31_baldwinstairs.jpg.ad905f891158de3c0b901ee32c65cb26.jpg

View attachment 1393

View attachment 1393

/monthly_2010_09/572953dd1be31_baldwinstairs.jpg.ad905f891158de3c0b901ee32c65cb26.jpg