Interesting. I most often see nutted bolts with welded nuts and washers, though the video didn't mention them. Surprised the expansion anchor has such a high capacity. Also been advised the expansion anchors get sketchy on permitter bolting due to overtightening and break out.

All are subject to competent install. Theoretically, every cast anchor is easily verifiable prior to pour though the IBC only requires periodic inspection. Most post installed mechanical anchors are usually only inspected periodically as required by the IBC. I have seen enough poorly installed post installed anchors that they make me nervous. I have also found smaller anchor bolts and empty boxes on jobs laying near the installed anchors than what is specified on the plans, which also makes me a little skeptical. Adhesive anchors are supposed to be continuously inspected. I have always wondered if that actually happens.

I wish bolts were marked with more information for my own edification, but I assume the engineers and special inspectors know a lot more than I do. I have wonder if engineers build enough overkill into anchorage to account for the fact that some just won't be as effective.

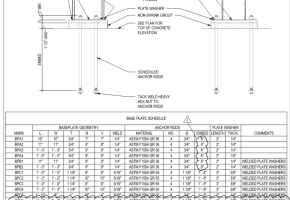

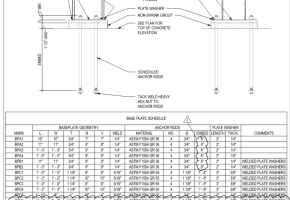

Working on a plan right now. They specify headed bolts, with periodic inspections. It is up to the installers to follow the plans and get it right.

I built a shop a few years ago. Monolithic, with J-bolts. I did not wet set them, I used a plastic placement device attached to the forms. Concrete still pushed them around and I had to manipulate some to get them back to plumb and depth, which I think kind of defeated the anti-wet set idea. I suspect most j bolts are wet set, which makes it worse IMO.