rosegamble

REGISTERED

Hi All,

I've been hired to design a four-unit townhouse project - my first townhouse project.

I want to get this fire-rated wall right. The 2021 IRC allows two methods of creating this wall without a sprinkler: two 1-hour rated walls or one 2-hour common wall.

No interest in the one 2-hour common wall due to difficulties with penetrations and sound concerns.

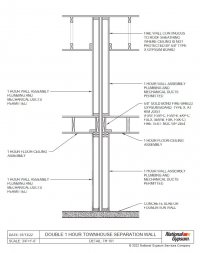

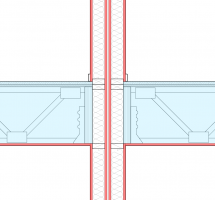

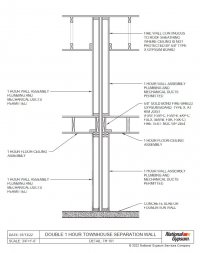

See "Option 1" attached here, from National Gypsum. This is two 1-hour rated walls (rated from both sides I presume). I like this from a penetration perspective. All MEP penetrations are free to run in the stud cavities in each wall. However, my floor/ceiling joists are going to run the opposite way which presents some difficulty at the floor intersections (for example, how to make the interior side of the fire-rating continuous from top to bottom).

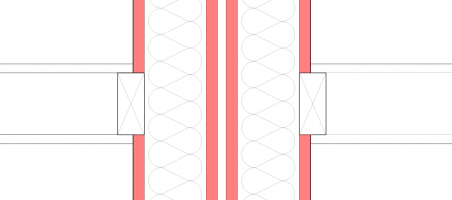

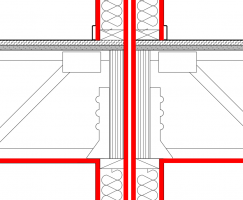

I found this "alternate" design online which is kind of neither method (two 1-hour rated walls or one 2-hour common wall) - see Option 2 attached here. It consolidates a 2 hour rating into the gypsum board panels in the center of the assembly, meaning the interior drywall is not rated and penetrations can move freely in these stud cavities. Since all the rating is happening in the center, my floor intersection issue is also negated.

Any thoughts? Would love to hear your experiences. Do you all have a UL approved detail you like to use? Struggling to find these online.

I've been hired to design a four-unit townhouse project - my first townhouse project.

I want to get this fire-rated wall right. The 2021 IRC allows two methods of creating this wall without a sprinkler: two 1-hour rated walls or one 2-hour common wall.

No interest in the one 2-hour common wall due to difficulties with penetrations and sound concerns.

See "Option 1" attached here, from National Gypsum. This is two 1-hour rated walls (rated from both sides I presume). I like this from a penetration perspective. All MEP penetrations are free to run in the stud cavities in each wall. However, my floor/ceiling joists are going to run the opposite way which presents some difficulty at the floor intersections (for example, how to make the interior side of the fire-rating continuous from top to bottom).

I found this "alternate" design online which is kind of neither method (two 1-hour rated walls or one 2-hour common wall) - see Option 2 attached here. It consolidates a 2 hour rating into the gypsum board panels in the center of the assembly, meaning the interior drywall is not rated and penetrations can move freely in these stud cavities. Since all the rating is happening in the center, my floor intersection issue is also negated.

Any thoughts? Would love to hear your experiences. Do you all have a UL approved detail you like to use? Struggling to find these online.