mauromj

REGISTERED

I am building a 40x60 2x6 stick frame shop. The foundation crew poured my walls at 40' 2" x 60'. Unfortunately, my trusses have already landed and they are 40' on the dot.

What options do I have to make these work?

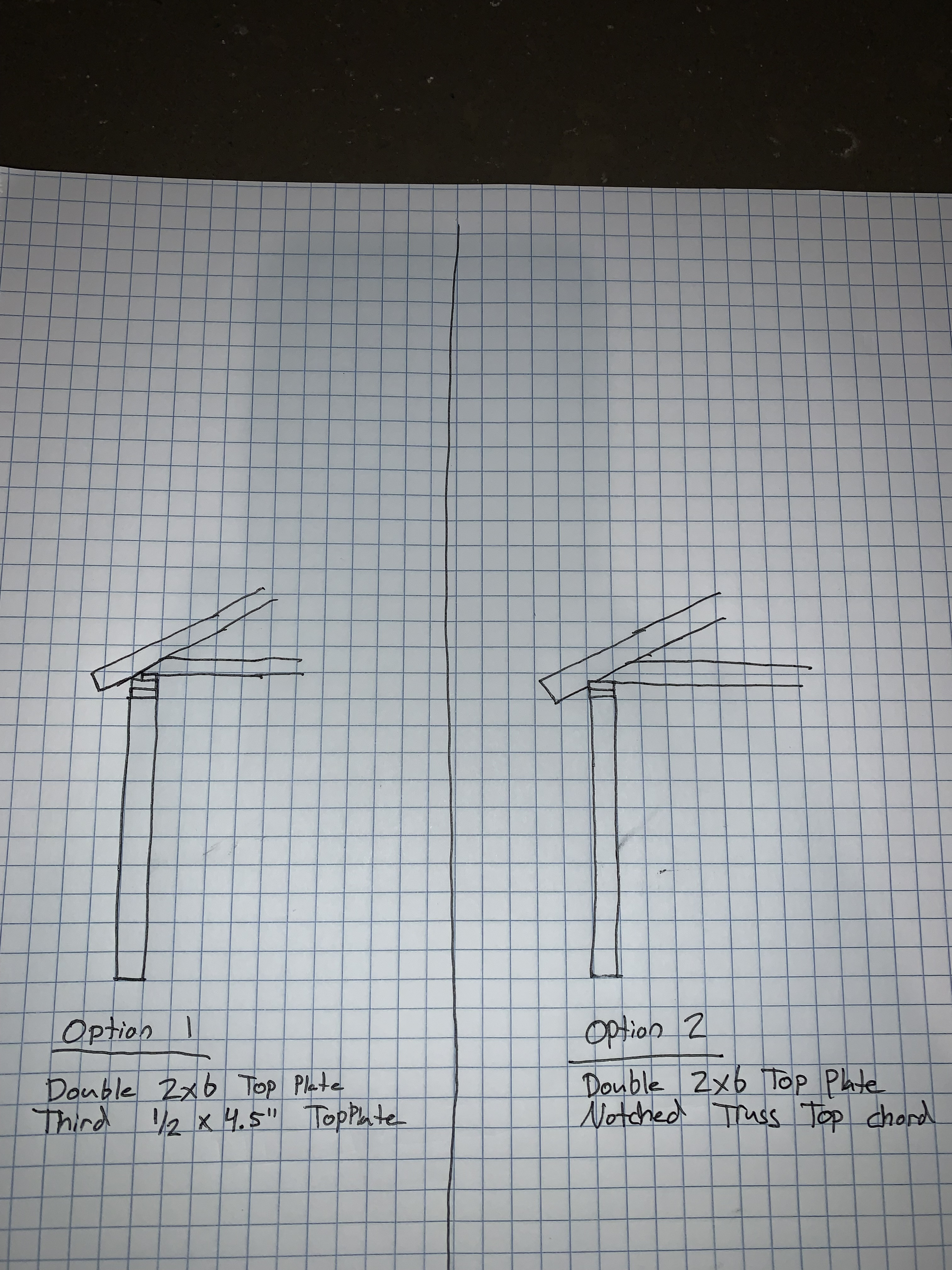

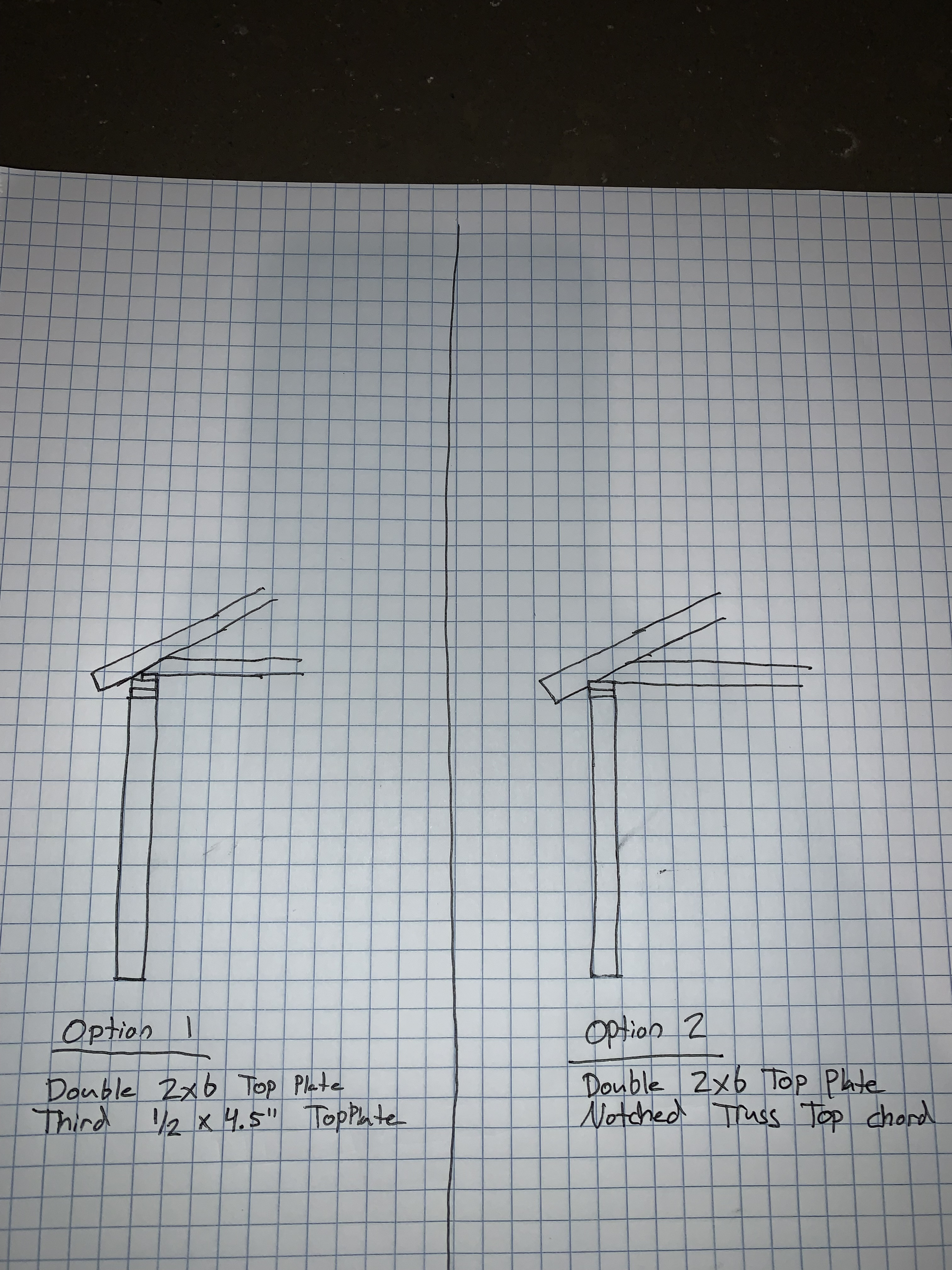

I can think of the following 2 options:

1. Place a third "top plate" on my ridge cap. I am thinking a 1/2" x 4.5" strip of plywood all around the top would do. I don't need much height to get my truss tails to clear.

2. Notch (birds mouth cut) the top chord of the truss. Again, I wont need much here. The notch would be 1" long, by 1/2" or so in depth. Very minimal for my 2x6 top chord. It would be barely noticeable, and I am sure it wont affect the structural integrity of the truss by much (if anything at all).

Would both solutions meet code in WA state? What would you do if you were framing it?

Here is a picture illustrating both options.

What options do I have to make these work?

I can think of the following 2 options:

1. Place a third "top plate" on my ridge cap. I am thinking a 1/2" x 4.5" strip of plywood all around the top would do. I don't need much height to get my truss tails to clear.

2. Notch (birds mouth cut) the top chord of the truss. Again, I wont need much here. The notch would be 1" long, by 1/2" or so in depth. Very minimal for my 2x6 top chord. It would be barely noticeable, and I am sure it wont affect the structural integrity of the truss by much (if anything at all).

Would both solutions meet code in WA state? What would you do if you were framing it?

Here is a picture illustrating both options.