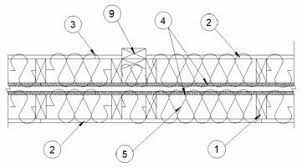

I am using UL 341 assembly in our project. Normally what I see is that the drywall will be run continuously behind all non-rated wall connections.

I am now working with a new sub contractor who refuses to run the drywall behind the non-rated wall so I told him to do the following detail as provided in the assembly

Can someone tell me what the purpose of the sides of the U-framing are? To me, it looks like you are just providing a fastening location at the end of the gyp so there is no gap for the fire to get into the wall. Also insulating the 3.5" cavity created by the U never gets completed.

Couldn't this be accomplished by running a 2x6 behind the 2x4 (#9) of the non-rated wall so that there is 1" overhang on each side and use that for the drywall and prevent any gaps that fire could enter through, and not installing the sides of the U-framing

Thoughts on this, I know this is a tested assembly but have any other configurations been tested, an L or the solution I am suggesting?

I am now working with a new sub contractor who refuses to run the drywall behind the non-rated wall so I told him to do the following detail as provided in the assembly

Can someone tell me what the purpose of the sides of the U-framing are? To me, it looks like you are just providing a fastening location at the end of the gyp so there is no gap for the fire to get into the wall. Also insulating the 3.5" cavity created by the U never gets completed.

Couldn't this be accomplished by running a 2x6 behind the 2x4 (#9) of the non-rated wall so that there is 1" overhang on each side and use that for the drywall and prevent any gaps that fire could enter through, and not installing the sides of the U-framing

Thoughts on this, I know this is a tested assembly but have any other configurations been tested, an L or the solution I am suggesting?