Last edited by a moderator:

-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

UV killed it?

- Thread starter ICE

- Start date

gfretwell

Silver Member

My guess is it was regular THHN

jar546

CBO

Yes, it appears to be THHN/THWN which is not UV rated and this is the result. We do not allow exposed THHN/THWN for installations like this where they are exposed.

Dennis

REGISTERED

I believe there is some THHn/THWN such as Thwn-2 that is sunlight resistant. The sunlight resistant conductors are black in color thus red, blue, etc are not sunlight resistant

• mTW or Thhn or ThWn-2Conductors shall be UL-listed Type MTW or THHN or THWN-2* gasoline and oil resistant II, suitable for operations at 600 volts as specified in the National Electrical Code. Sizes 14

through 1 AWG shall be rated VW-1, larger sizes shall be listed for CT use. Sizes 2 AWG and larger listed and marked sunlight-resistant in black only. Conductors shall be annealed

copper, insulated with high-heat and moisture resistant PVC, jacketed with abrasion, moisture, gasoline, and oil resistant nylon or listed equivalent, as manufactured by Southwire Company or approved equal.

Dennis

REGISTERED

My understanding is that the nylon jacket is just a protective covering and not an important part of the conductor.

Here is an excerpt from an IAEI-- Gil is from the IAEI and Dave is Dave Mercer from Southwire

Here is an excerpt from an IAEI-- Gil is from the IAEI and Dave is Dave Mercer from Southwire

When Gil visited us previously, he made a splash by noting that the transparent nylon covering THHN/THWN, while arguably making them sexy compared to THW, is not required to maintain the conductor's dielectric properties. Therefore, if in the course of installation the nylon suffers the odd nick, or unsightly run, or even is scraped off, the conductor is fine so long as the insulation underneath remains intact. Learning this much, we had to have Dave over for more of the story.Unless conductors are exposed to gasoline or oil, or submerged for an extended period we're talking many months--the nylon covering offers strictly a mechanical protection, Dave explained, with the underlying PVC supplying the dielectric properties as Gil had told us. The nylon actually is stripped away for the UL acceptance test. Therefore, if the nylon is scraped off, but the plastic underneath is intact, an appropriate response usually is "Good; it's done its job," and a green tag.

Dennis

REGISTERED

I guess I should have quoted the entire excerpt for those interested

When Gil visited us previously, he made a splash by noting that the transparent nylon covering THHN/THWN, while arguably making them sexy compared to THW, is not required to maintain the conductor's dielectric properties. Therefore, if in the course of installation the nylon suffers the odd nick, or unsightly run, or even is scraped off, the conductor is fine so long as the insulation underneath remains intact. Learning this much, we had to have Dave over for more of the story.Unless conductors are exposed to gasoline or oil, or submerged for an extended period we're talking many months--the nylon covering offers strictly a mechanical protection, Dave explained, with the underlying PVC supplying the dielectric properties as Gil had told us. The nylon actually is stripped away for the UL acceptance test. Therefore, if the nylon is scraped off, but the plastic underneath is intact, an appropriate response usually is "Good; it's done its job," and a green tag.

It's not just the nylon covering on THHN/THWN, we learned, but the sheaths on cable assemblies also often are optional. A cable installer nicked the sheath of a nonmetallic cable installed in a dry indoor location, and responded in a curious way: he turned the cable so the nick faced toward the wall. Not a bad response, Dave opined (while not wholeheartedly endorsing); this way, people glancing at it in passing wouldn't be unnecessarily concerned.

You may detect from this that Dave is quite an engaging speaker; moreover he's one with 19 years' product and Code experience under his belt to give plenty of clout to the information.

Damage is not necessarily limited solely to cable sheaths, of course. If a cable appears damaged, Dave recommends cutting a window in the sheath so you can examine the conductor insulation beneath. If that's good, you can "reinstall the window."

What should you do when you do want to, or need to, repair a cable sheath? Vinyl tape does just fine, Dave said, except in a wet location, and self-sealing mastic tape does even better. Best is a layer of self-fusing tape covered by a layer of vinyl. It even can be used outdoors on UF or SE cable, so long as it is not buried. For that, you need the sealing coverings that come with a Listed underground splice kit.

Art asked whether NM or SE cable repaired in this way still meets the UL standard. Dave commented that it is tough to say. There needs to be a dialogue between the manufacturer, AHJ, and installer. A qualified installer of repair materials should be able to make a repair acceptable to the AHJ, and Southwire's warranty will remain in effect. "Qualified?" Jim Wooten asked. "Someone who has received certified training in using the material, either in an apprenticeship class, or continuing education such as is offered by tape manufacturers." Even damaged Medium Voltage cable remains warrantied, so long as the shielded jacket, which is there for mechanical protection like that of MC, is fixed using a Listed repair kit installed by a qualified person.

We hope to co-sponsor such a class with 3M or Raychem or some such organization

Thanks Dennis,

Would you happen to know when THWN-2 became available?

In this case I have a hapless homeowner that is doing work himself. It started with removing a bearing wall between the kitchen and living room. There is an expired permit for a swimming pool that had to be dealt with and the kitchen remodel has new circuits from the bootlegged service.

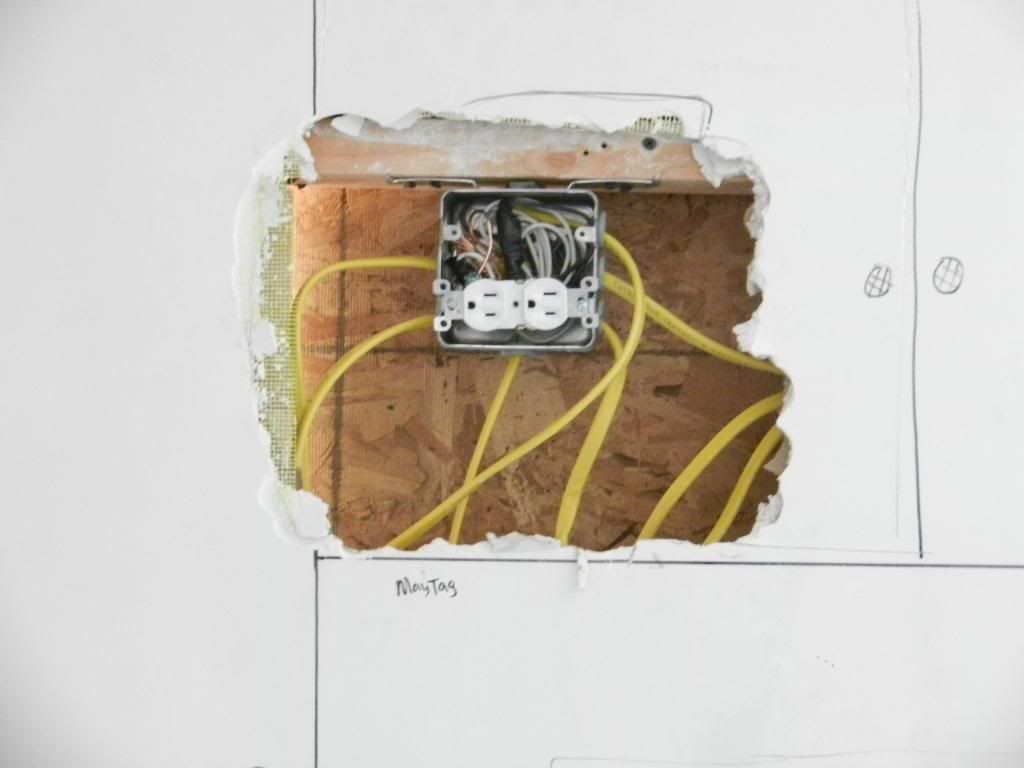

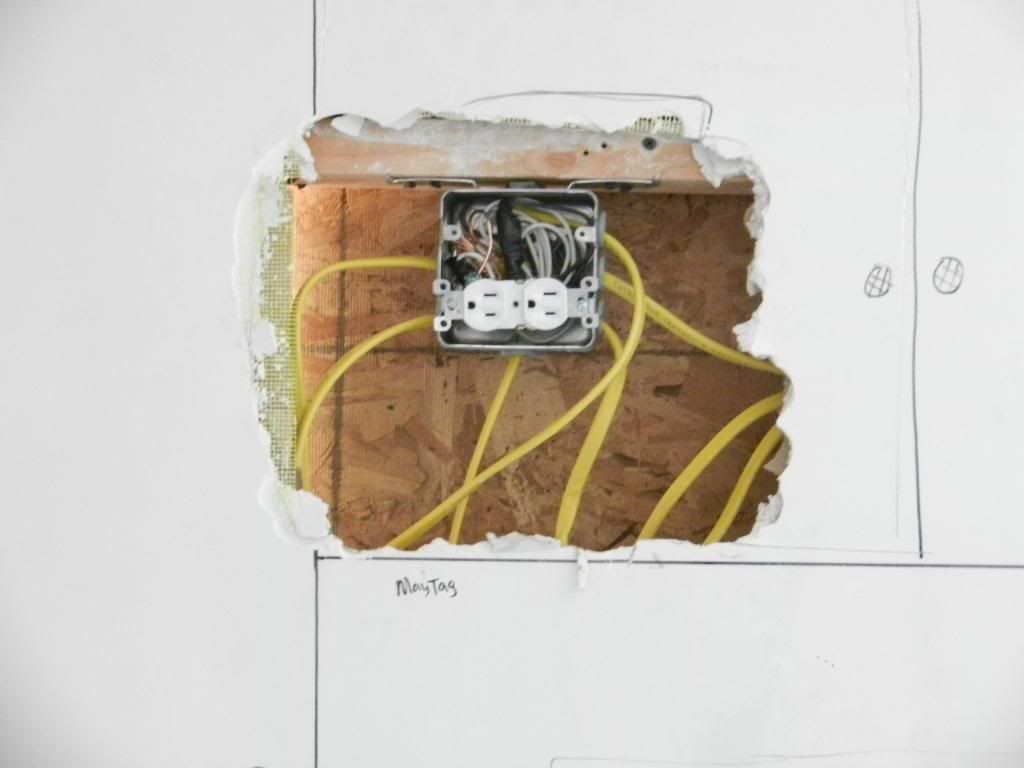

Here is an example of the owners best effort that I posted previously. The wad of taped up white wires are who knows what....stripped wire twisted together and taped up. No wire nuts etc.

The owner and his wife are mid twenties and bought the house six months ago. The have amazing attitudes of entitlement. They talk to me like I work for them and they wish I didn't. They yell and make demands. They "Know their rights".

And here I am trying to find out if I really need to cause them the expense of replacing the service entrance conductors. On my own time.

Well don't get the idea that I am going out of my way to help them. Not even close. I do this because I want to know and understand. I want to get it right.

This is over the kitchen sink. This one mistake has generated ten minutes of loud complaining. Every mistake that's made becomes my mistake because I didn't tell them about the mistake before the mistake was made. If it were up to them, I would have been in the room when the project idea was first conceived. I hope everybody is pleased with the paint colors because, if not, it will somehow be my fault.

They make a point of telling me what every mistake costs. They asked "What should I do with this window"? And added "Home Depot isn't going to take it back. Do you want the window? Should I donate it? There's no way to make this work? Why aren't you helping us? What else aren't you telling us until it's too late? Are you going to bail us out when we run out of money? What happened to serving the public? You do work for us you know."

And that's just the little woman.

Would you happen to know when THWN-2 became available?

In this case I have a hapless homeowner that is doing work himself. It started with removing a bearing wall between the kitchen and living room. There is an expired permit for a swimming pool that had to be dealt with and the kitchen remodel has new circuits from the bootlegged service.

Here is an example of the owners best effort that I posted previously. The wad of taped up white wires are who knows what....stripped wire twisted together and taped up. No wire nuts etc.

The owner and his wife are mid twenties and bought the house six months ago. The have amazing attitudes of entitlement. They talk to me like I work for them and they wish I didn't. They yell and make demands. They "Know their rights".

And here I am trying to find out if I really need to cause them the expense of replacing the service entrance conductors. On my own time.

Well don't get the idea that I am going out of my way to help them. Not even close. I do this because I want to know and understand. I want to get it right.

This is over the kitchen sink. This one mistake has generated ten minutes of loud complaining. Every mistake that's made becomes my mistake because I didn't tell them about the mistake before the mistake was made. If it were up to them, I would have been in the room when the project idea was first conceived. I hope everybody is pleased with the paint colors because, if not, it will somehow be my fault.

They make a point of telling me what every mistake costs. They asked "What should I do with this window"? And added "Home Depot isn't going to take it back. Do you want the window? Should I donate it? There's no way to make this work? Why aren't you helping us? What else aren't you telling us until it's too late? Are you going to bail us out when we run out of money? What happened to serving the public? You do work for us you know."

And that's just the little woman.

Last edited by a moderator:

jar546

CBO

Excellent job on the fire foam between studs under the window. Why are you giving them such a hard time ICE?

It's the tiger in me.jar546 said:Why are you giving them such a hard time ICE?

Expect the unexpected.

http://www.wimp.com/oldtruck/

Last edited by a moderator:

Dennis

REGISTERED

Can't help with that but I would guess somewhere between 2002-2008. That wire may very well be thhn and not thwnICE said:Thanks Dennis,Would you happen to know when THWN-2 became available?

I'm leaning towards voiding the permit and requiring a licensed electrical contractor for a new permit.

If I had my way, all electrical work would be done by qualified electricians and housewives wouldn't get involved.

It's not that women shouldn't be considered during a kitchen remodel. For example putting the switch to the garbage disposal four feet from the sink...that's not an accident.

If I had my way, all electrical work would be done by qualified electricians and housewives wouldn't get involved.

It's not that women shouldn't be considered during a kitchen remodel. For example putting the switch to the garbage disposal four feet from the sink...that's not an accident.

Last edited by a moderator:

electriclese

Bronze Member

Is this near salt water? Lots of corrosion going on. Looks like ace ventura did the bends on that conduit.

Dennis

REGISTERED

I don't get you on this. Do you think there should not be a switch near the sink?ICE said:For example putting the switch to the garbage disposal four feet from the sink...that's not an accident.

RJJ

Co-Founder

Only if your plan is to get rid of the wife!

You're obviously too young to remember this but.....Dennis said:I don't get you on this. Do you think there should not be a switch near the sink?

When garbage disposals first hit the market, many electrical contractors put the switch far enough away that a person couldn't have one hand in the disposal and the other hand on the switch.

Dennis

REGISTERED

I think Darwin had it right. Only the strong survive. If you want to put your hand in there and turn on the switch then I think you should. :devilICE said:You're obviously too young to remember this but.....When garbage disposals first hit the market, many electrical contractors put the switch far enough away that a person couldn't have one hand in the disposal and the other hand on the switch.

"Too young to remember" Ha- at 62 I haven't heard that in a long long time.