This is my first post on this forum, so please be gentle.

While I’m new here, I’m not a virgin. I’ve been trolling this site, off and on, as a guest for quite a while. I appreciate the respectful discourse and helpful nature of the professionals on this forum. However, my real motivation for engaging now is not purely altruistic.

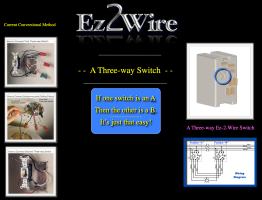

I need help with a unique and challenging business venture that exceeds my expertise and skill sets. I need to build a team of electrical industry professionals to help validate, test, and advance my patented concept. I need individuals who can ascertain and help facilitate the necessary NEC TIAs that will be required to advance this technology shift.

I don’t mean to be elusive in my venture description, but I respect the rules of this forum and don’t want to get bounced on my first post.

First Question…

Is it inappropriate for me to solicit this type of assistance on the forum? Assistance that could lead to a compensated position within our start-up business?

Second…

Would it be inappropriate to post a link to a brief (5-minute) introduction video I’m hosting on Vimeo?

Once again... I'm doing this to see if any forum members would be interested in joining my team.