-

Welcome to The Building Code Forum

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

An average day

- Thread starter ICE

- Start date

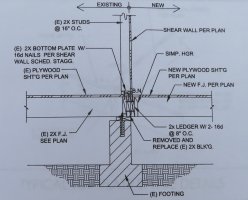

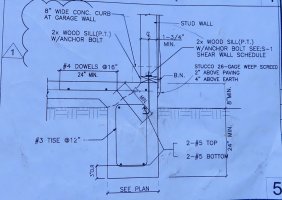

The plan calls for a two pour system with #4 dowels. The dotted line is the cold joint between the footing and the slab. We refer to it as a "shovel off". Dowels are usually bent 90°. Dowels must be tied in place.

Ok so there's no dowels. The first question is how would the concrete be piled 22" above the grade beam not to mention the lack of rebar at the top of the footing.

The form board sits on the #3 ties. The Strong Wall may not be all that strong.

Ok so there's no dowels. The first question is how would the concrete be piled 22" above the grade beam not to mention the lack of rebar at the top of the footing.

The form board sits on the #3 ties. The Strong Wall may not be all that strong.

Last edited:

Msradell

SAWHORSE

That drawing is very confusing. To me it looks like what they are calling #4 Dwls @ 16" look like rebar in the slab. The bar at an angle that I call out to be 12" minimum looks very strange and as you said it doesn't look like there's any way to tie it in.The plan calls for a two pour system with #4 dowels. The dotted line is the cold joint between the footing and the slab. We refer to it as a "shovel off". Dowels are usually bent 90°. Dowels must be tied in place.

Ok so there's no dowels. The first question is how would the concrete be piled 22" above the grade beam not to mention the lack of rebar at the top of the footing.

The form board sits on the #3 ties. The Strong Wall may not be all that strong.

Around here I've never seen a cold joint place like that either, they are normally flat across at the top of the grade beam. Were you seeing a need to have concrete 22" above the grade beam? It looks like it's just 8" to the sill plates.

The way it is set up there would be a 22” space between the grade beam and the top of the slab.

Odd design...So is there rebar exiting the first pour through the "cold joint" into the second pour-slab? Looks like there's a horizontal bar, would that be tie to the slab mat before the slab pouring?The plan calls for a two pour system with #4 dowels. The dotted line is the cold joint between the footing and the slab. We refer to it as a "shovel off". Dowels are usually bent 90°. Dowels must be tied in place.

Ok so there's no dowels. The first question is how would the concrete be piled 22" above the grade beam not to mention the lack of rebar at the top of the footing.

The form board sits on the #3 ties. The Strong Wall may not be all that strong.

Wheres conarb?...conarb stat!

I usually don't pay attention to roof work unless I am there for a reason. Passing by is not a reason.

This is two doors away from an inspection that turned into a non-inspection. That contractor started with a re-roof permit for the house but not the garage. I left a correction that asked him to obtain the permit for the garage. I also noted that there is a shiny new furnace vent poking out the roof so perhaps he needs a mechanical permit ...and just for the sake of wasting ink I included,"And anything else that has been done without a required permit". The house was vacant and locked. There was plywood covering the windows and locked gates kept me in the front yard.

Another inspector followed up when the contractor requested a final inspection of the roof. That inspector was able to get into the house. He wrote a correction to obtain permit for a kitchen remodel.

My second visit was today. I was there for another attempt at a final inspection. Sure enough, there's a new kitchen....along with the rest of the house.

I wrote correction to obtain permits for two bathrooms remodeled, all windows replaced, all new lights, receptacles and switches. I am pretty sure that the building was re-wired but I haven't been in the attic.

Can lights must have been on sale.

Back to that bootleg roof:

Ya roofing is better left alone....but sometimes I go off the deep end and stick my nose, well you know what I mean.......don't you.

This is two doors away from an inspection that turned into a non-inspection. That contractor started with a re-roof permit for the house but not the garage. I left a correction that asked him to obtain the permit for the garage. I also noted that there is a shiny new furnace vent poking out the roof so perhaps he needs a mechanical permit ...and just for the sake of wasting ink I included,"And anything else that has been done without a required permit". The house was vacant and locked. There was plywood covering the windows and locked gates kept me in the front yard.

Another inspector followed up when the contractor requested a final inspection of the roof. That inspector was able to get into the house. He wrote a correction to obtain permit for a kitchen remodel.

My second visit was today. I was there for another attempt at a final inspection. Sure enough, there's a new kitchen....along with the rest of the house.

I wrote correction to obtain permits for two bathrooms remodeled, all windows replaced, all new lights, receptacles and switches. I am pretty sure that the building was re-wired but I haven't been in the attic.

Can lights must have been on sale.

Back to that bootleg roof:

Ya roofing is better left alone....but sometimes I go off the deep end and stick my nose, well you know what I mean.......don't you.

Last edited:

conarb

REGISTERED

I see what they are trying to do, they are trying to build a standard foundation like a monolithic pour without pouring the slab at the same time, I've thought about it and don't see anything wrong with it, the 22" gap between the top of the cage and the top of the pour is highly unusual, but again I don't see anything wrong with it, I guess Tiger can request a structural observation from the DPoR since it's at variance with the plans, maybe he would request vertical dowels, or maybe he would sign it off.Odd design...So is there rebar exiting the first pour through the "cold joint" into the second pour-slab? Looks like there's a horizontal bar, would that be tie to the slab mat before the slab pouring?

Wheres conarb?...conarb stat!

steveray

SAWHORSE

I didn't think the wire nuts had the "wings" 40 yrs ago.....?

TheCommish

SAWHORSE

keen observation ICE, flowing on, it think 40 years all wire nuts came in any color of black you wanted

Well I don't know about wings and color from forty years ago. I do see small wire spliced with big wire so as you guys are suggesting, there is more to the story.

The next two service upgrades were done by licensed contractors. They give as good as they get. Apparently they didn't get enough to do good.

This enclosure is held to the wall with one screw. The guy said,"Well it went all the way through the stucco".

You can see the cable going out the rear. He didn't attempt to disguise the hole in the wall.....or a patch of any sort.

The next panel has a bigger hole so he tried to mitigate that.

You can see the cable at the bottom. The hole is all the way to the top.

Now that was a big hole....it looks like part of the previous service cabinet is still there.

This outcome is typical. Once upon a time it was a clean well-kept neighborhood that deserves better.

This enclosure is held to the wall with one screw. The guy said,"Well it went all the way through the stucco".

You can see the cable going out the rear. He didn't attempt to disguise the hole in the wall.....or a patch of any sort.

The next panel has a bigger hole so he tried to mitigate that.

You can see the cable at the bottom. The hole is all the way to the top.

Now that was a big hole....it looks like part of the previous service cabinet is still there.

This outcome is typical. Once upon a time it was a clean well-kept neighborhood that deserves better.

Last edited:

steveray

SAWHORSE

Almost everyone deserves better these days.....Except those that deserve worse...

TheCommish

SAWHORSE

ICE, if a metal plate was placed over the old service panel hole before the new surface mountepanelle was installed woud that be allowed?

If the arrangement kept water out of the wall and there were no splices behind that plate and no holes in the back of the panel enclosure....well then.....probably not.ICE, if a metal plate was placed over the old service panel hole before the new surface mountepanelle was installed woud that be allowed?

tmurray

SAWHORSE

Cellulose?

These are dryer vents. One for each condo located on each side of the wall. The ducts enter the slab floor. The nearest exterior wall is 20 ft. away....I didn't find a termination there or anywhere else. The contractor couldn't find it either.

The wall between the laundry rooms is being rebuilt due to fire damage. The electric dryer in unit A burst into flames.

This is the inside of the dryer vent.

One of the garages is full of insulation. The second story attic suffered smoke damage. There's no fireblocking or draftstops.

The wall between the laundry rooms is being rebuilt due to fire damage. The electric dryer in unit A burst into flames.

This is the inside of the dryer vent.

One of the garages is full of insulation. The second story attic suffered smoke damage. There's no fireblocking or draftstops.

Last edited:

north star

MODERATOR

- Joined

- Oct 19, 2009

- Messages

- 4,596

$ ~ $

The "copper colored" metal flashings around the vertical vent

pipes isn't copper at all......True copper would have oxidized

by now.........That appears to be some type of manufactured,

colored flashing to match tile roofing.

$ ~ $

The "copper colored" metal flashings around the vertical vent

pipes isn't copper at all......True copper would have oxidized

by now.........That appears to be some type of manufactured,

colored flashing to match tile roofing.

$ ~ $

The flashing is galvanized steel painted to match. The tile looks newer than the flashing.$ ~ $

The "copper colored" metal flashings around the vertical vent

pipes isn't copper at all......True copper would have oxidized

by now.........That appears to be some type of manufactured,

colored flashing to match tile roofing.

$ ~ $