tbz

SAWHORSE

Ok,

This might seem like an odd question but I have always looked at the bottom landing measuring point to be the same as the nose to nose measuring point of the treads.

Example:

This might seem like an odd question but I have always looked at the bottom landing measuring point to be the same as the nose to nose measuring point of the treads.

Example:

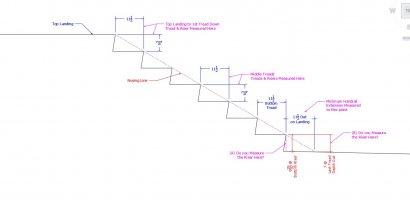

- Risers are measured from the tip of the nosing line of a tread to the next same point on the tread below.

- For the Top landing the starting nosing point to the nosing point of the tread below

- But when you get to the bottom landing, do you measure at the riser or to the landing at a point equal to the last tread depth, like the handrail extension is required to be?