mark handler

SAWHORSE

Sounds like the OP needs to verify the connection details, or add ties.....Rider Rick said:What happens when you approve something that fails and someone gets hurt God forbid.

Your premier resource for building code knowledge.

This forum remains free to the public thanks to the generous support of our Sawhorse Members and Corporate Sponsors. Their contributions help keep this community thriving and accessible.

Want enhanced access to expert discussions and exclusive features? Learn more about the benefits here.

Ready to upgrade? Log in and upgrade now.

Sounds like the OP needs to verify the connection details, or add ties.....Rider Rick said:What happens when you approve something that fails and someone gets hurt God forbid.

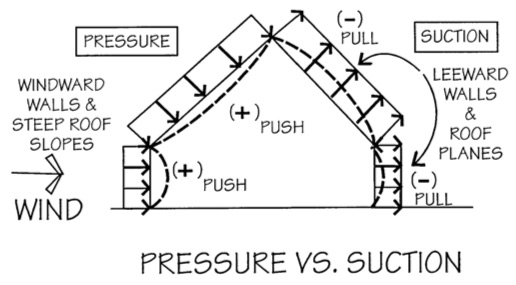

It doesn't, but if you do not follow the prescriptive requirement of ties, you need to, per engineering standards show how you are preventing the "spread" of the RR and the reactions at the connection pointsGBrackins said:I guess I'm confused, could someone point me to the section of the 2009 IRC that requires metal connectors for a prescriptive rafter to ridge connection? Thanks!

Yes, based on the size and location of the ties and fasteners. Talk with your Structural engineer....GBrackins said:so then if you toe-nail plumb cut rafters to a ridge board with a collar ties ran under the ridge board attached to the sides of the rafters and you provide ceiling joists/rafter ties then you're good?

How about the ceiling or collar tie question? not the metal connector question?Yankee said:I don't see where a metal connector is required to be used with a structural ridge as long as bearing is met. Although some might require a stamped engineered design for a structural ridge, I generally don't, and approve them using "standard engineering practice". Meaning, if the ridge beam is calculated properly for loading by the supplier, or sized properly as a built-up-beam by the contractor, I am comfortable approving the roof assembly with or without metal connectors.

And what happens when you omit the ties?Jobsaver said:. The ties should extend laterally to the opposing rafter and fastened to the rafters according to this table.

You may not omit the ties without then providing a structural ridge. Is that an answer to your question a few posts below? Or are you asking something else?mark handler said:And what happens when you omit the ties?

and how do you provide the structural ridge connection to Roof Joists without metal hangers?Yankee said:You may not omit the ties without then providing a structural ridge. Is that an answer to your question a few posts below? Or are you asking something else?